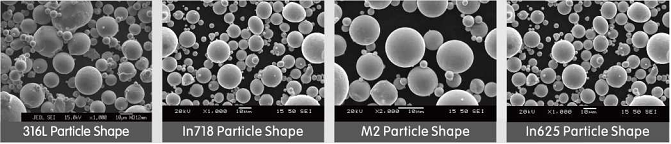

The alloy powder made by vacuum atomization has the advantages of complete spherical powder, good fluidity, even distribution of alloy elements, low oxygen content good corrosion resistance, heat resistance, wear resistance, etc. it is suitable for 3D printing, spray welding, laser cladding and other process materials

Characteristics

High Sphericity & High Flowability.

specifications

| Chemical composition of metal powder | |||||||||

| Products | Chemical composition(%) | ||||||||

| Alloy | Cr | Ni | Mo | V | Si | Mn | Nb | C | Fe |

| 316L | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.0 | ≤2.0 | ≤0.03 | Bal | ||

| 304L | 18.0-20.0 | 8.0-12.0 | <1.0 | ≤2.0 | ≤0.03 | Bal | |||

| 17-4PH | 15.5-17.5 | 3.0-5.0 | Cu:3.0-5.0 | ≤1.0 | ≤1.0 | 0.15-0.45 | ≤0.03 | Bal | |

| 420J1 | 12.0-14.0 | ≤0.6 | ≤1.0 | ≤1.0 | 0.15-0.25 | Bal | |||

| 430 | 16.0-18.0 | ≤0.75 | ≤1.0 | ≤0.12 | Bal | ||||

| H13 | 4.75-5.5 | 1 1-1.5 | 0.8-1.2 | 0.8-1.2 | 0.2-0.5 | 0.32-0.45 | Bal | ||

| M2 | 3.75-4.5 | 4.5-5.5 | 1.75-2.2 | 0.2-0.45 | 0.15-0.4 | W.5.5-6.75 | 0.78-0.88 | Bal | |

| 310S | 24.0-26.0 | 19.0-22.0 | <1.5 | .≤2.0 | 0.2-0.45 | Bal | |||

| S136 | 12.0-14.0 | 0.15-0.4 | 0 8-1.0 | ≤1.0 | 0.2-0.45 | Bal | |||

| CoCrMo | 26.5-30.0 | ≤1.0 | 4.5-7.0 | ≤1.0 | ≤1.0 | Co:Bal | ≤0.35 | ≤1.0 | |

| Physical properties of magnetic powder | ||||||

| Products | Process | Liquidity (S/50g) |

T.D (g/cm³) |

0.C.ppm (ppm gas) |

Specifications (μm) |

Packing (kg) |

| 316L | Gas atomization |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| 17-4PH | Gas atomization |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| M2 | Gas atomization |

<20 | ≥5.0 | ≤600 | 15-50 | 5/25/50 |

| In718 | Gas atomization |

<20 | ≥4.7 | ≤600 | 15-50 | 5/25/50 |

| In625 | Gas atomization |

<20 | ≥4.6 | ≤600 | 15-50 | 5/25/50 |

| AISi12 | Gas atomization |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

| AISi10Mg | Gas atomization |

<20 | ≥5.0 | ≤500 | 15-50 | 5/25/50 |

Application

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy