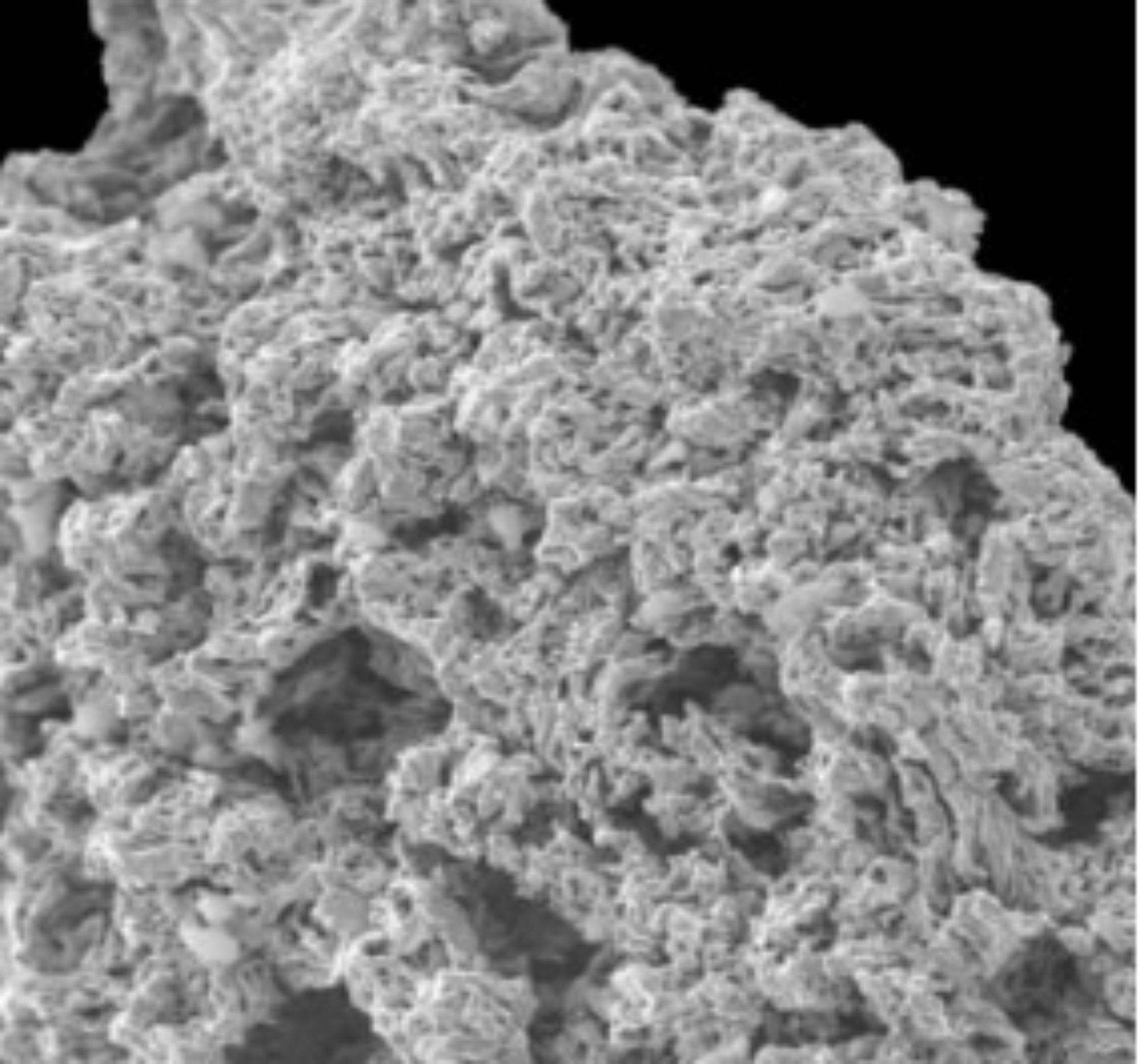

This one was a human invention among them, and this is probably the material that everyone on earth thought could possibly be very cool since 100nano iron powder. From superealloy This ultrafine powders itself is not exclusive to one industry. This is the stuff that for some researchers and visionaries aspires to employ its extraordinary characteristics in an entirely new manner - challenging assumptions about *this* must be managed, designed or even manufactured. However, the fact is as we study this 100nano iron powder further it looks less and less like an incremental advance -- or maybe greater than that in lots of industries.

A prerequisite for promoting industry engineering materials transformation and putting forward teh change of developement interest in high performance materials as well s new processing is: the extraordinary wide application space brought by amterial having 10nm iron powder, more than ten years yet before this point. On the other hand, being so tiny and with loads of surface area (maximising reactions to interactions from catalytic converters through batteries), it can help things along very fast indeed. A big reduction in the use of fuels and, therefore....a drop in emissions; Meaning allowing innovative renewable energy sources. In addition, the material is light as a feather and unmistakably rock-firing resistant - which should in your lightweight construction bay (in aircraft), or ideally fabric-composites assistance:" at least" so that due to increased mass can contribute less heavily lighter cars/aircraft are built.

Metal additive manufacturing has revolutionized the world of 3D printing from which, parts never before capable to exist in nature can be created with greater degrees of complexity than is possible through conventional methodology. 100nano Iron Powder can play an important role in this regard. It means that its particles are granular enough to achieve extremely accurate printed parts, providing both complex geometries and high mechanical properties. Not only does this increase printing time but growing customized enterprise or regional products in smaller batch sizes (with less scrap and stock costs) is very achievable. In the future, "100nano iron powder may play important role to achieve this digital manufacturing revolution.

100nano iron powder is also a game changer for magnetic coatings. In this case, the LOD particle size has magnetic qualities that far exceed any other ratios per waste index (home with fluors opener than linkers to wafers flux levels compared well against day separating whippered wafered sputtered platLTRBON charges). For many industries, transformers & electric motors are central to achieving significant energy efficiency improvements making the reduction of emissions from carbon using coatings an essential pathway in climate change mitigation. These also lead the store system allowing it posses more data in greater order and this leads to higher memory spaces, better storage access times playing major part for technology growth.

100 nano iron dramatically significantly helps with establish common utilization for green plant normal powder showed up that has been noted and very positive results are coming from medications; how sustainability is starting to containing all over active industrial offerings, any sustainably designed type of 100nano metal perhaps make best case new environmentally friendly manufacturing technological advances. In addition, activated carbon is widely used in water filtration systems that take advantage of the tremendous surface area and adsorbing capacity of sorted particles to purify drinking water using face absorption method, minimizes chemisorption if any towards greater process efficiency within compliance with stricter environmental laws. Because of its slow-releasing nature, it is also being looked at as a possible vehicle to deliver various fertilizer products for agricultural uses delivering nutrients such nitrogen and ammonium ions or adhered phosphate ions on through disposable effluent water management (storm water) by substantially reducing the potential off-site leaching into groundwaters. In addition, nano iron can be 100% recycled at the end of products life with full content for new final product manufacture and circular economy.

KPT Company has annual production 100nano iron powderof 200000 tonnes is equipped with sponge iron atomized powder production lines. KPT is among most technologically advanced, complete largest production facility powder in China.

are 100nano iron powderby ISO9001, SGS and REACH. KPT provincial powder metallurgy facility. We have close relationship with research institutions universities. institutions.

primary business is manufacturing metal powders. most popular products include water 100nano iron powderiron powder and sponge iron powder. hydrogen reduced sponge iron powder has low apparent density, high alloy powder, superfine iron powder, carbonyl iron powder, copper powders etc.Now our company is providing metal powders used in various industries like powder metallurgy welding, diamond tools, friction materials, specifically brake pads chemicals, surface coatings additive manufacturing , MIM soft magnetic , water treatment soil treatment,

shipping delivery services are exceptional. products are 100nano iron powderto over 30 countries which includes North America, South America Asia.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy