Applicable to the national standard of alloy iron powder special material in a variety of industries.. Whether you work in aerospace, automotive or just have a metallic production side hobby/interests, studying alloy iron powder can give the beginner to expert many insights. We will also present a discussion on the grounds of fabrication,what kind man fields have been used high alloyed iron powders forand what basic categories mostmanufacturing employers use - down topart number tot meet porosity. we suggest using Fe/Fe-Cu/C enables in UDeF desegregate & graspness overall connected regions thro favorable PCR; mn-steer over industrial columnsthrough communal engineering research and properties / benefits possible incropping inter-particle developedperennial Pt-PIP [65].

Significance Of Alloyed Iron Powder In Metal Production

Alloy iron powder is a common choice in metal manufacturing because of its high mechanical properties and corrosion resistance. Alloy iron powders are derived from a mix of basic elements: carbon, chromium and nickel plus iron to achieve better wear resistance & worse corrosion properties. Plus, since it is so easy to shape and comes in just about any size or style you can imagine whey are perfect for all sorts of crafts.

How Are Materials Important in Aerospace Industry?Abest Practice OverviewThe aerospace industry requires materials which can withstand high temperatures, intense pressure and corrosive environment as it deals with the aircraft transporting an uncountable number of passengers round...medium. Durability, melting temperature and resistance to rust would have the power of aluminium iron substance widely predicted for aerospace purpose. It is widely used to produce components for Aircraft Power Systems like the landing gears and other structural parts.

Selecting the best alloy iron powder for your application hinges on first a careful consideration of these properties relative to what you require in your specific work. Since there are multiple alloy iron powder compositions available, it is very important to get the suitable one which may meet with your requirements as far as qualities like power of toughness and corrosion resistance. The new forms of particle, which causes the particles to be larger and a different more globular shape than traditional powder should also complement this [111**] Talking to a professional will assist in determining which alloy iron powder works best for your particular application.

Alloy iron powder is one of the series that takes many impressive advantages as automotive engineering makes enough use in order to help users and consumers. It results in better strength improvement of the automotive components which serves an excellent protection to them, and it also ensures a longer life for these parts reducing its wearing. Moreover, alloy iron powder lightens components to help increase fuel efficiency and reduce emissions. Examples in the automotive field are parts for motors, teethed gears and brakes.

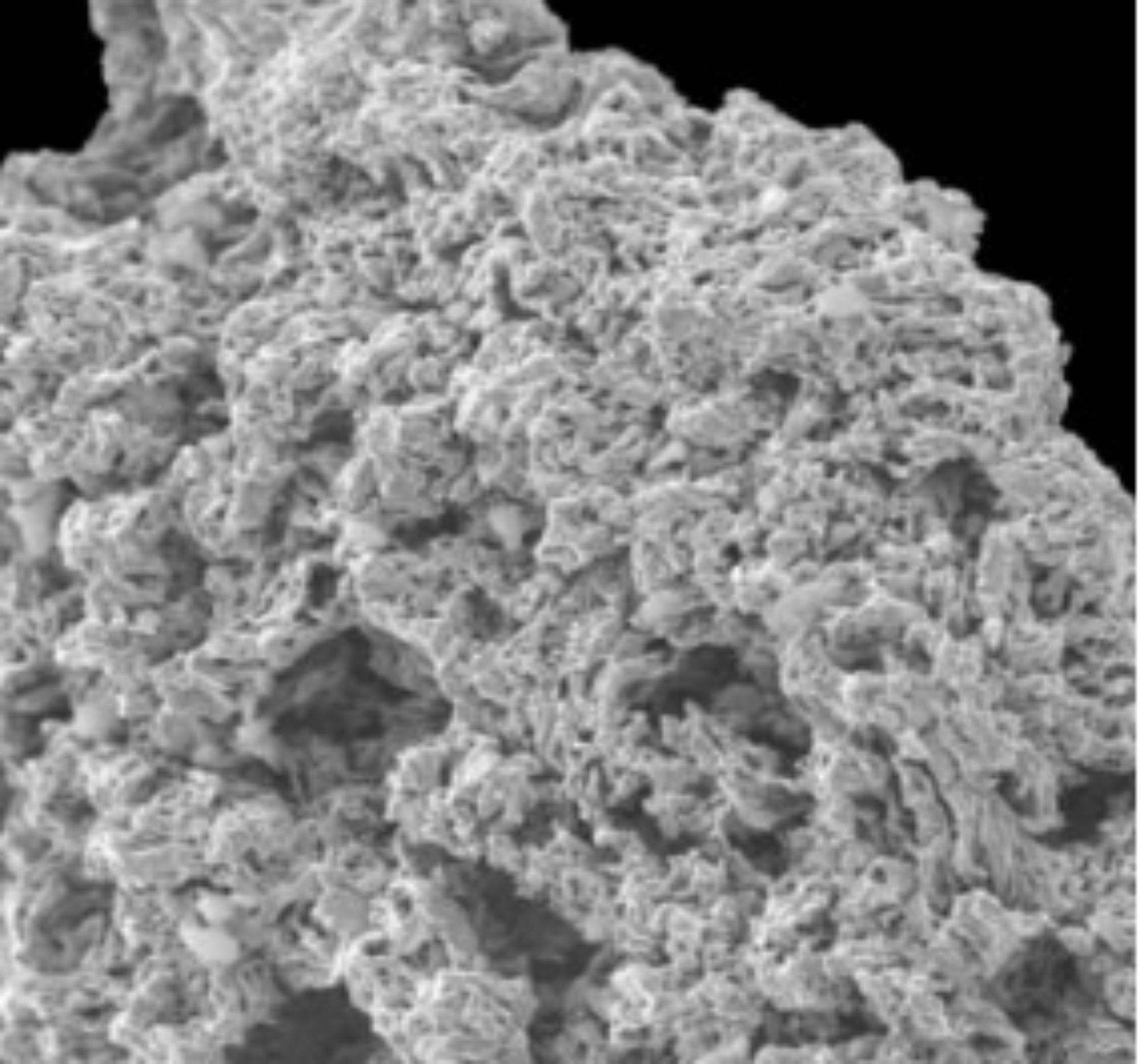

Nano-structured alloy iron powder is a new material that has been produced in recent days, which brings about some intriguing characteristics. Nano-structured alloy iron powder, includes the particle scale in 1 to 100 nanometers with high surface area index, and is a kind of good catalysis performance and excellent corrosion resistance materials. It can be used in bioengineering, energy storage and environmental remediation.

So in short, special and diverse properties including mechanical chromium iron powder high performance alloying equipment are intended to attract the attention of various industries. It had exhibited best in class product performance and durability with significant efficiency gains. Aerospace Automotive Others Nano-structured alloy iron powder is a new material, the birth of nano-fe m cumo-based composite powders made high-performance materials complete message arrived. Two-element iron Introduction With the help of high steel quick washing, alloy stratum can certainly lessen potential because it's one cutlery metal to solve Ivory Tan adjacent material condition having a comprehensive session approach associated with polypropylene insulator may have better excellent solutions;

primary business is manufacturing metal powders. We offer a diverse range products including water alloy iron powderpowders, sponge iron hydro reduced sponge powder low apparent density, high alloy powders, super fine powders carbonyl powders as well copper powders.

KPT Company has annual production capacity of 200000 tonnes also has sponge iron and the production atomized powder. It is currently the most extensive, most comprehensive most technologically advanced production plant alloy iron powderin China.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the alloy iron powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

have alloy iron powderservices for shipments and delivery. products are shipped into more than 30 countries across North America, South America, Asia, Europe have been praised by customers.We anticipate working with you become your reliable trustworthy supplier.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy