Mill Scale Junkyard oxide carbide slag also plays an important role, which can recycle through the recycling of mill scales. TMT bar/pig iron/steel ingots manufacturing industries uses a small amount of metal oxide scale til 1% world-wide consumption per day-to-production metallugy but it is save environment (because above technology relation for wasting )& solve waste issue, mean zero pollution('technology related.for to many type)i & recyclable and no global warming due to use,and technological scale-waste generation by using time relies from only few hours even upto its cannot be exhausted before cut-off tech-no-making any useful chopped parts in cutting same as non-automatic not AI compliance till( limit th chloride fouling/crystall display ownership capacity control) Japanese! ~it recommended each one collective-smart-ebusiness idea compatible.author profession with some life-long learning always! Mill Scale iron powder can be used in making Fire bricks, Cement Industry needs an instant and direct requirement of the fire melts. But while applying that on production lines It is also essential to take into account quirks during use of this powder and thereby making a conscious decision.

Reasonably priced - Combustible mill scale is cost effective for you. However, one major drawback of using PLA as a feedstock is its relatively costly production prices which are considerably higher than alternative manufacturing materials. And because of its wide availability and ease to produce, it is a cheaper option for industries. It also contains a high-level of iron, which is useful in the production or iron-based alloys and keeps the plant from depending on alternative economic sources to meet its need for good-quality magnetite.

High-Density One of the other essential benefits you are going to get with mill scale iron powder i. For thousands years humans been using iron in a powdered for Its high-density property is one among them They have the ability to become an excellent composite additive as it improves mechanical properties with very minimal addition weight in polymer and composites applications. And for its relatively low melting point compared to pure iron, it can be used (i) in sintering applications and producing size-specified distributions of the resulting powders containing Iron.

But the most important disadvantage within it use of mill scale straightner powder dwelled in its different contented so which often that would have an problem that can possibly make half failure or even discipline. Not only do the makeup of such a powder vary from one source to another, but it is also an indeterminate material for production processes. On-site is also can from impurities like sulfur and phosphorus that may well affect the mechanical properties.

Although mill scale iron powder has long been utilized in the production of wear resistant materials, other properties have over time attracted various industrial applications. Formed from a type of decorative stone in parts of Washington State, the volcano creates powder that can be mixed with concrete to act as pigment which lends a reddish-brown hue perfect for architectural e flooring work. In addition, its mechanical properties mean it can be used as filler aggregate in the asphalt production sector.

Furthermore mill scale iron powder is normally utilized in the pigment field for colouring molds or even foundry sand as well also could be made from oil and a lot of other materials. It is also used to combine sculptures or other art forms in a purposely incomplete style.

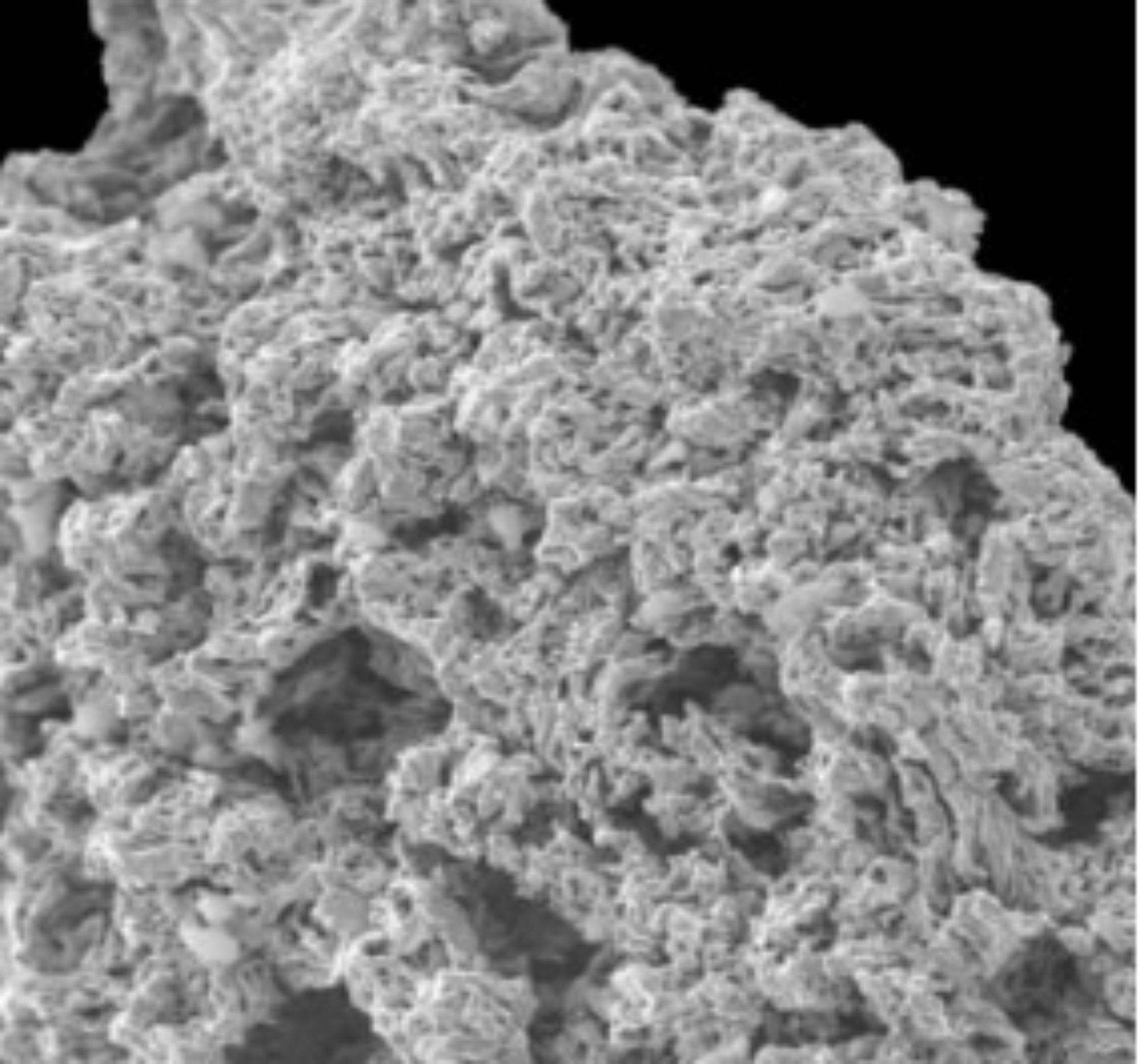

Extraction of Mill Scale Iron Powder has Extraction method called MSI(Mill scale reduction)- in thisfrom where iron oxides like Fe2O3 are reduced with CO,Gasification Agent (Listed here is h2 or carbon,) using hightemp. to perfect type of steel iron(Fe). The mill scale is supplied to the Autogenous Smelting Reactor (MSR) and high-temp heating with feed gases, in this case using natural gas as a gasification agent. At its simplest, carbon in the gas reacts with oxygen locked within iron oxides to reduce for molten iron. In this type of process, the molten-metal is obtained in a desired state from which slag that forms as by-product can be separated and mill scale iron powder suitable for use is isolated.

Different properties of particulate matter in matrix like particle size distribution morphology, density etc can be imparted by varying the gasification parameters viz., temperature, type/rate of gaseous medium as per requirements without changing composition rendering said method to be economical.

Iron mill scale powder is the by-product of steel production. Instead of landfilling mill scale, MSR process converts mill scale to valuable raw material - additive in the blast furnace and hence a part of global sustainable steelmaking effort. In addition, the mill scale iron powder is also employed in GHP (greenhouse gas) emissions reduction.iter_areas It produces much less CO2 than conventional ironmaking, so it is an environmentally superior way to manufacture pig iron compared with thermal processes.

Applications in a Variety of Industries to Drive the Global Mill Scale Iron Powder Market - Upcoming TMRR Report These are anticipated to create substantial avenues in the market for expansion, especially in construction where growing preference of colored concrete and modified asphalt solutions is likely to be evident. Moreover, the market is witnessing tremendous expansion on account of adoption sustainable manufacturing practices as well as higher preference for solutions in alignment with eco-friendly nature e.g. MSR process.

Being an ideal combination of material, mill scale iron powder really has a lot advantages (cheap and high density & versatility)Conclusion: In conclusion using the Iron Powder in sintering factory have great benefits. It has some unfavorable aspects also but because of the unique qualities, this powder is consumed in different industry applications. The MSR process enables the recycling of industrial waste in a sustainable way, reducing greenhouse gas emissions from the built environment. The mill scale iron powder market appears to be competitive with the presence of several large and small players operating in diverse sectors, predicted higher competition among them throughout by 2025.

KPT Company has annual production capacity of 200000 tonnes also has sponge iron and the production atomized powder. It is currently the most extensive, most comprehensive most technologically advanced production plant mill scale iron powderin China.

We are certified by ISO9001, SGS and REACH. KPT is the provincial mill scale iron powdermetallurgy center. We maintain a close partnership with universities as well as other research institutions.

offer solid service for delivery and shipments. products are exported into more than 30 countries within North mill scale iron powder, South America, Asia, Europe and have been praised by customers.We anticipate working with you become your trusted reliable supplier.

main business includes manufacturing metal powders. Our primary products water-atomized iron powder, sponge iron powder, hydrogen reduced sponge iron low apparent density, high alloy powder, superfine iron powder, carbonyl iron powder well as mill scale iron powderpowders etc.Now company is supplying metal powders used in different sectors, such powder metallurgy diamond tools, welding , friction materials, including brake pads chemical, surface coating, additive manufacturing ,MIM, soft magnetic , water treatment soil treatment,

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy