The Amazing World of Powder Metallurgy 3D Printing

Do you wonder how things are manufactured? Think about constructed things from metal? Do you realize that there is a special technology makes metal things faster and safer?

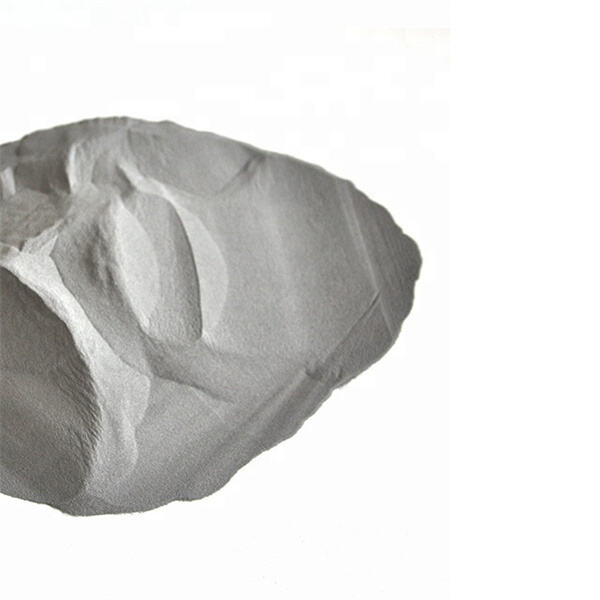

That special technology called Powder Metallurgy 3D Printing. It is a real solution to produce things out of metal powder. The metal powder is heated up and melted together to help make the plain thing you want. And it's all done due to the help of a special machine.

It's an innovative new and method innovative in of metal things using metal powders. This technique is quickly becoming the go-to technology industrial manufacturers would you like to increase safety and effectiveness in their production lines.

Powder Metallurgy 3D Printing is an additive manufacturing that creates a three-dimensional object layer by layer, like powder 3d printing created by KPT. The procedure involves using a high-powered laser heat melt the getting metal powder used in the construction associated with object. The powder is layered and fused together, developing a seamless and highly detailed last product is incredibly strong and durable.

There are lots of advantages to using Powder Metallurgy 3D Printing, including metal powder for 3d printing by KPT into the manufacturing industry. Firstly, it is an easy and efficient way of complex metal as it removes the importance of complex tooling and assembly processes. This saves time, cash and reduces the risk of errors.

Secondly, Powder Metallurgy 3D Printing reduces wastage of materials as only the desired amount of metal powder is used to generate the thing.

Thirdly, Powder Metallurgy 3D Printing enhances safety in the workplace since it minimizes the handling of hazardous materials required in traditional metal manufacturing methods. This decrease in hazardous materials handling is beneficial when it comes to security of this workers, as well as for the environmental surroundings.

Powder Metallurgy 3D Printing is a technology which was available for over 10 years but has been gaining traction the manufacturing industry because of its ability to create complex shapes, structures, and geometrics at high speeds, same with KPT's stainless steel powder for 3d printing. The innovation is based on the capability to reduce steadily the cost of metal production while increasing the speed at which objects is done.

In addition, the technology happens to be able to incorporate the utilization of various metal powders, including steel, titanium, and aluminum, for the manufacturing of objects with different properties. These properties include strength, durability, and weight, typical essential factors the style and creation of metal objects.

The use of Powder Metallurgy 3D Printing poses little to no risk to human health being unlike traditional steel manufacturing methods which require the handling of dangerous materials such as molten metal, just like the titanium 3d printing powder built by KPT. The metal powder used in the procedure is deemed safe for managing, additionally the process is undertaken in a controlled environment minimizes any risk of contamination.

The process of Powder Metallurgy 3D Printing reduces wastage, which reduces the amount of metal scrap that will require safe disposal. This decreases the environmental consequence of manufacturing and manufacturing.

Using Powder Metallurgy 3D Printing, as well as the 3d metal printing powder by KPT requires a knowledge of how the technology functions together with materials used. To start out the procedure, metal powder is loaded to the machine, in addition to design regarding the object is uploaded to your software. The equipment then utilizes a high-powered laser selectively melt and fuse the metal powder together layer by layer, creating a three-dimensional object.

To attain the best results, it is important to decide in the sort that's true of and adhere to safety protocols whenever loading and handling it to the machine.

primary business is manufacturing metal powders. have a wide selection of powder metallurgy 3d printingthat include water powders that atomized, sponge iron, hydrogen reduced sponge powder low apparent densities, high-alloy powders super fine powders including stainless steel, carbonyl powders copper powders, more.

provide excellent powder metallurgy 3d printingin terms of delivery shipping. Our products are sold to more than 30 countries within North America, South America, Asia, Europe and have been acknowledged customers.We hope to work with you become the reliable and solid supplier.

annual capacity of KPT Company's production 200000 tons. Additionally, it has atomized powder as well as production lines sponge iron. It is currently the most extensive company, with the most complete, powder metallurgy 3d printingadvanced production plant powder in China.

are powder metallurgy 3d printingby ISO9001, SGS and REACH. KPT provincial powder metallurgy facility. We have close relationship with research institutions universities. institutions.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy