Iron powder pyrites, a virtually ubiquitous material in various industrial spheres and extra abundant on the ornamental scale. More than just fool's gold, treasure trove of new metals source from the stuff that technology is made; 'Gold' and Silver'A Growing List Of Metals Mined From Minerals Below: Controling How More And Unlike These Materials Can Be Extracted/stdcnewswell Posted on December 10th. TOP 5 MAJOR USES OF PYRITES IRON POWDERS

So, Efficiency is one of the cornerstone traits in getting somewhere in industries and pyrites iron powder has a major part to play over there. The 3D printable material which speeds up chemical reactions and eliminates energy utilisation by increasing the processes productivity at low cost. This makes it extremely useful for catalysis and reducing agents in a variety of industrial applications including metal extraction or refining that results to production at more sustainable rates while maintaining efficiency.

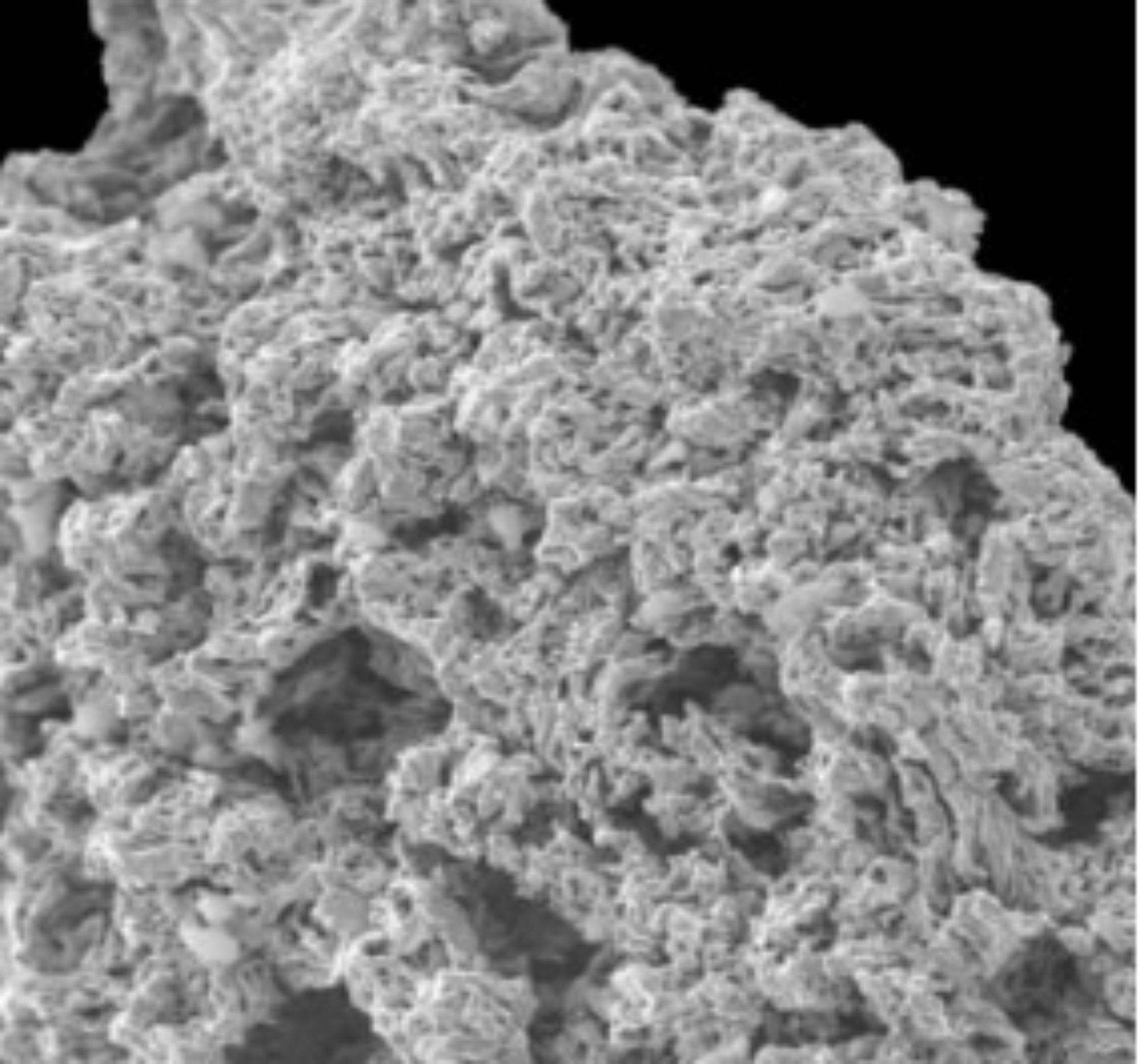

Pyrites, iron powder we see that it is efficient for the availability point of view then apparently not a pure cube but other than this deficiency has lots more advantages. It has lower particle size that improves the surface area, so hence higher mixing and better reaction kinetics in industry. To produce sintered parts which are going to be strong and have good overall microstructure - this method is indispensable. Additionally, it has low content of impurity in its purity which is getting richer material that most industry need today especialy electronics and aerospace industries.

Due to the environmental issue, sustainability is also in a worldwide scale throughout industries and pyrites iron powder significantly plays an important role as raw material for reducing CO2 emission or other potential environment impacts during manufacturing process. Being used in some processes helps to decrease and reduce the greenhouse gases emitted when smelting ore, which can replace traditional iron ores. In addition, since it can be employed in a number of chemical reactions, hydrogenation with [bmim][Cl] is an efficient process generating no more waste than water and saving energy as if its nickname were 'the simple solution for green chemistry'. This allows for a closed-loop economy to the point where iron powder is reusable an easily recycled resource that lessens waste disposal problems.

Word Count Approx: 237Metallurgy integrates heavily on product quality for which only pyrites iron powder can be used at its best. MIMplus components perform extremely well in metal injection moulding due to their uniform particle size and up to 99.9% purity, with high production accuracy even for complex parts that require minimal subsequent rework following milling requirements. It not only saves raw materials but also scraps and dumps. It acts both as regenerative additives and for making iron being regulated by delivering material properties, of which the alloy is also a part under some metal production conditions. Pyrites iron powder is a smart material at the heart of numerous metalwork advancements, from wear-resistant hard-facing alloys to custom-made magnetic materials.

offer solid service for delivery and shipments. products are exported into more than 30 countries within North pyrites iron powder, South America, Asia, Europe and have been praised by customers.We anticipate working with you become your trusted reliable supplier.

primary business is manufacturing metal powders. most popular products include water pyrites iron powderiron powder and sponge iron powder. hydrogen reduced sponge iron powder has low apparent density, high alloy powder, superfine iron powder, carbonyl iron powder, copper powders etc.Now our company is providing metal powders used in various industries like powder metallurgy welding, diamond tools, friction materials, specifically brake pads chemicals, surface coatings additive manufacturing , MIM soft magnetic , water treatment soil treatment,

KPT Company has annual production pyrites iron powderof 200000 tonnes is equipped with sponge iron atomized powder production lines. KPT is among most technologically advanced, complete largest production facility powder in China.

have obtained certifications like ISO9001, SGS, REACH, etc. KPT the pyrites iron powderpowder metallurgy facility. maintain a close partnership universities as well other research institutions.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy