Iron Carbide Powder, An Exceptional Material Transforming The Way Innovation And Technology Is Made This rare, remarkable 99.5% pure compound is changing the way manufacturing occurs and creating new opportunities in a range of different fields. However, it delves a bit deeper into the details of what this is and how it's revolutionizing technology.

Transforming Manufacturing Processes

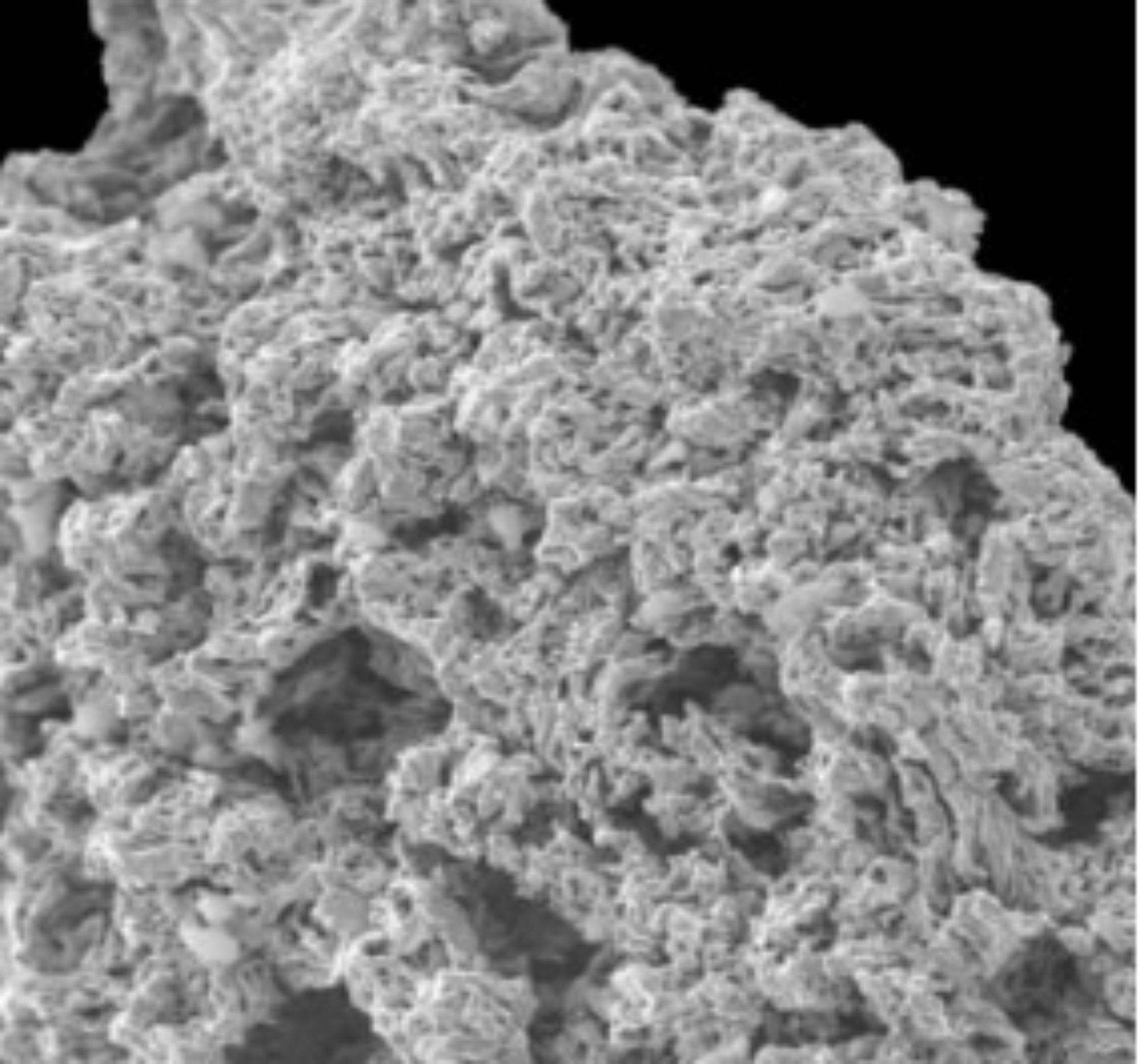

While not a new compound, this ultrafine (+99.5% pure) form of iron carbide (Fe3C), is the first to enable clean and direct reduction processes needed for composites evolution through Additive Manufacturing or Austenitization-Growth Transformation processing. Manufacturers can use this refined version to make components with stronger mechanical properties, increased wear resistance and better thermal stability. Combining high purity ultrafine iron carbide powder with advanced manufacturing such as sintering and PVD allows manufacturers to make thinner, stronger layers that have a decreased level of porosity so they are more efficient overall.

99.5% Purity in Iron Carbide Powder Explained

The fact that you can get iron carbide powder to 99.5%pure is not just a number, it defines the threshold where we will be able display select excellent performance characteristics Poor purity, even in trace amounts, can have a marked effect on the structure of the material during processing and compromise itegrity. The increased purity also means dependable composition, especially for highly accurate manufacturing such as in semiconductor fabrication or advanced aerospace component production. In addition, the higher purity also prevents any contamination during high-temperature processes driving to manifest of its natural properties as a material.

Eco-friendly attributes of utilizing Ultrafine Iron Carbide Powder

Sustainability and Green industry(2019) In todays era, Sustainability and eco-friendliness are massive driving forces in the industry. High purity ultrafine iron carbide powder positively supports these goals by enhancing the efficiency of manufacturing, minimising wastage and energy consumption as compared to lower grade alternatives. Along with prolonging the lifespan of a product, this powder requires fewer replacements in general which can contribute to an even lower carbon use over all. With production methods heading more and more towards closed-loop recycling, every thing matters making use of the respect to some sort of circular economy.

Applications in Many Industries

Industries across the universe right from automotive to electronics are hopping unto 99.5% purefine iron carbide, this ultra fine material has not shown some visible benefits which regular powder uses but offer exceptional results with a high level of purity required for such metals in machinery and equipment industry today It is an important technology in the shift to building lighter, more fuel-efficient engines for markets that can tolerate extreme conditions prevalent within automotive sector. It is used by electronics manufacturers in magnetic components and semiconductors, to improve conductivity and heat dissipation. Our technology also boosts the solar cells and wind turbines parts of renewable energy. This gives a sense of how this material may be used as an enabler for innovation in many sectors.

High Purity Iron Carbide Powder Offering Top-Notch Technology Of The Future

The future is with a large purity of ultrafine iron carbide powder, which the company states can be up to 10 times higher than traditional carburizing materials. It is creating advances in nanotechnology by allowing the production of complex shapes like never before. In the field of quantum computing, its magnetic characteristics make it a possible building block for qubits with longer lifetimes needed in processing quantum information. With every new discovery and improvement of manufacturing process high purity iron carbide powder is bound to take a bigger part in research supporting technologies that seem near impossible.

So ultimately, they are classed as totally new in the field of material science rather than just another incrementally better alternative. It not only has its power in simplifying systems of production but is also known as a key for sustainability, which provides insights into adaptation with the environmental system pushing innovation through several sectors. This much is certain as there are no real substitutes: high purity iron carbide powder sits at the foundation of the coming years for tech and industry alike.