This kind of alloy powder is produced by vacuum atomization. Each particle not only has the same homogeneous chemical composition, but also has ultra-fine grain size, thus eliminating the macrosegregation of the second phase. Compared with the casting material it has higher tensile strength, better toughness and even material hardness.

Characteristics

Higher DC bias characteristics Higher saturation induction density

Lower core loss Better temperature stability

Better corrosion resistance

specifications

|

Physical properties of magnetic powder

|

|||||

|

Products

|

Process

|

D50 (um)

|

T.D

|

o.c.

|

Specifications (mesh)

|

|

(g/cm3)

|

(ppm gas)

|

||||

|

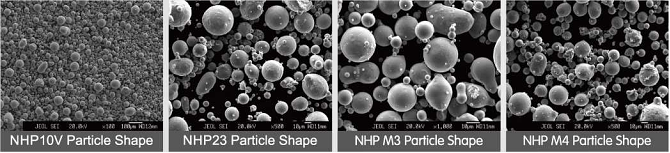

NHPM3

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|

NHPM4

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|

NHPT15

|

Gas atomization

|

50-100

|

≥5.0

|

≤600

|

40/500

|

|

NHPT15M

|

Gas atomization

|

50-100

|

≥4.7

|

≤600

|

40/500

|

|

NHP10V

|

Gas atomization

|

50-100

|

≥4.6

|

≤600

|

40/500

|

|

NHP23

|

Gas atomization

|

50-100

|

≥5.0

|

≤500

|

40/500

|

|

NHP30

|

Gas atomization

|

50-100

|

≥5.0

|

≤500

|

40/500

|

Application

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy