high-grade magnetic powder core.

Characteristics

Higher DC bias characteristics Higher saturation induction density

Lower core loss Better temperature stability

Better corrosion resistance

specifications

|

Chemical composition of metal powder |

||||||||||||

|

Products |

Chemical composition(%) |

|||||||||||

|

Fe |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Co |

Ni |

Al |

||

|

Hi-Flux |

Balance |

<0.05 |

<0.5 |

<0.5 |

<0.03 |

<0.03 |

<0.5 |

== |

== |

48-52 |

== |

|

|

MPP |

Balance |

<0.03 |

<0.5 |

<0.5 |

<0.03 |

<0.03 |

== |

1.8-2.5 |

== |

80-83 |

== |

|

|

FeSi |

Fe1.5Si |

Balance |

<0.03 |

1.0-2.0 |

<0.3 |

<0.03 |

<0.03 |

<1.0 |

== |

== |

== |

== |

|

Fe3.0Si |

Balance |

≤0.03 |

2.5-3.0 |

c0.3 |

<0.03 |

<0.03 |

<1.0 |

== |

== |

== |

== |

|

|

Fe4.0Si |

Balance |

<0.03 |

3.5-4.0 |

<0.3 |

<0.09 |

<0.03 |

<1.0 |

== |

== |

== |

== |

|

|

Fe5.5Si |

Balance |

<0.03 |

5.0-6.0 |

<0.3 |

<0.03 |

<0.03 |

<1.0 |

== |

== |

== |

== |

|

|

Fe6.5Si |

Balance |

<0.03 |

6.0-7.0 |

<0.3 |

<0.03 |

<0.03 |

<1.0 |

== |

== |

== |

== |

|

|

FeSiAl |

Balance |

<0.03 |

8.0-11.0 |

<0.3 |

<0.03 |

<0.03 |

<1.0 |

== |

== |

== |

4.0-7.0 |

|

|

Soft magnetic alloy powder |

||||||

|

Products |

Process |

D50 (卩m) |

A.D |

O.C. |

Specifications (mesh) |

|

|

|

|

|

|

|

|

|

|

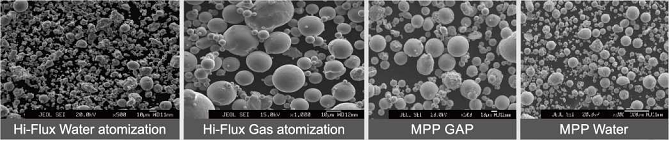

Hi-Flux |

Water atomization |

20-40 |

>3.9 |

≤3000 |

-150/-180 |

|

|

MPP |

Gas atomization |

20-40 |

>4.5 |

≤400 |

-150/-180 |

|

|

|

Water atomization |

20-40 |

>3.9 |

≤3000 |

-150/-180 |

|

|

|

Gas atomization |

20-40 |

>4.5 |

≤400 |

-150/-180 |

|

|

FeSi

|

Fel.5Si |

Water atomization |

20-40 |

>3.9 |

≤3000 |

-150/-180 |

|

Fe3.0Si |

||||||

|

Fe4.0Si |

Gas atomization |

20-40

|

>4.5

|

≤400

|

-150/-180

|

|

|

Fe5.5Si |

||||||

|

Fe6.5Si |

||||||

|

FeSiAl |

Gas atomization |

20-40 |

>4.5 |

≤400 |

-150/-180 |

|

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy