* Following ISO 9001 standard for quality certification

* The powder manufacturing process is green and pollution-free

* Sold worldwide

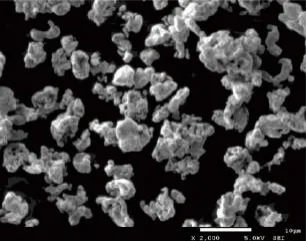

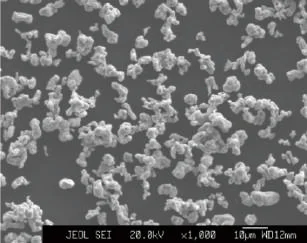

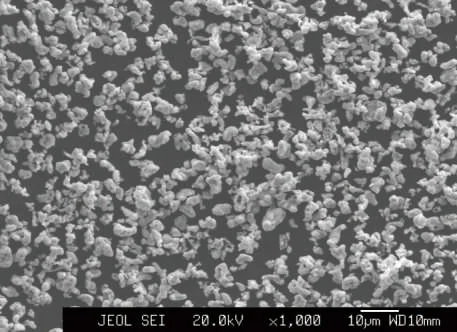

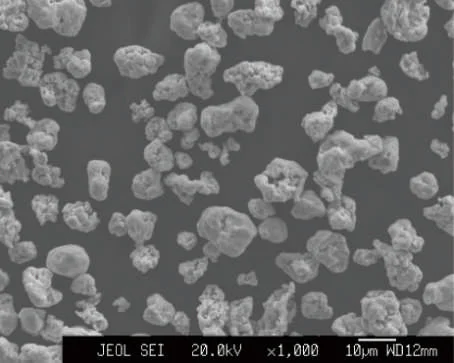

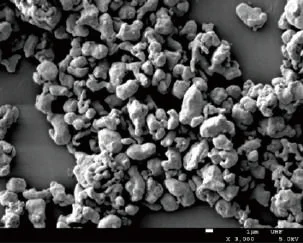

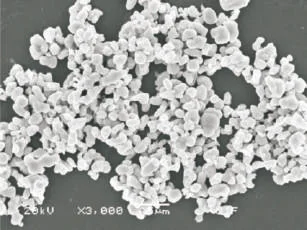

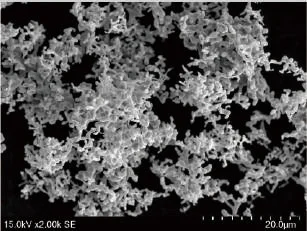

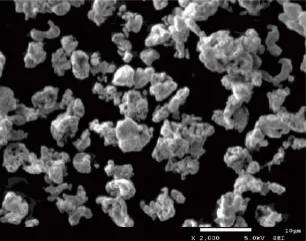

* Widely used in powder metallurgy, diamond tools, environmental remediation, electronic components and other industries