Aya masalah? Mangga ngahubungan kami pikeun ngawula ka anjeun!

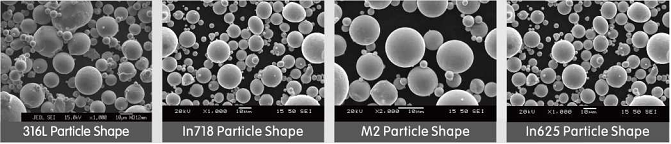

panalungtikanThe alloy bubuk dijieun ku atomization vakum boga kaunggulan tina bubuk buleud lengkep, fluidity alus, sanajan distribusi elemen alloy, eusi oksigén low résistansi korosi alus, résistansi panas, résistansi maké, jsb éta cocog pikeun percetakan 3D, semprot las, laser. cladding jeung bahan prosés séjén

ciri

Sphericity High & Flowability High.

spésifikasi

| Komposisi kimia bubuk logam | |||||||||

| produk | Komposisi kimia (%) | ||||||||

| logam campuran | Cr | Ni | Mo | V | Si | Mn | Nb | C | Fe |

| 316L | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.0 | ≤2.0 | ≤0.03 | madu | ||

| 304L | 18.0-20.0 | 8.0-12.0 | ≤2.0 | ≤0.03 | madu | ||||

| 17-4PH | 15.5-17.5 | 3.0-5.0 | Cu: 3.0-5.0 | ≤1.0 | ≤1.0 | 0.15-0.45 | ≤0.03 | madu | |

| 420J1 | 12.0-14.0 | ≤0.6 | ≤1.0 | ≤1.0 | 0.15-0.25 | madu | |||

| 430 | 16.0-18.0 | ≤0.75 | ≤1.0 | ≤0.12 | madu | ||||

| H13 | 4.75-5.5 | 1 1-1.5 | 0.8-1.2 | 0.8-1.2 | 0.2-0.5 | 0.32-0.45 | madu | ||

| M2 | 3.75-4.5 | 4.5-5.5 | 1.75-2.2 | 0.2-0.45 | 0.15-0.4 | W.5.5-6.75 | 0.78-0.88 | madu | |

| 310S | 24.0-26.0 | 19.0-22.0 | .≤2.0 | 0.2-0.45 | madu | ||||

| S136 | 12.0-14.0 | 0.15-0.4 | 0 8-1.0 | ≤1.0 | 0.2-0.45 | madu | |||

| CoCrMo | 26.5-30.0 | ≤1.0 | 4.5-7.0 | ≤1.0 | ≤1.0 | Co: Bal | ≤0.35 | ≤1.0 | |

| Sipat fisik bubuk magnét | ||||||

| produk | proses | Liquidity (S / 50g) |

TD (g/cm³) |

0.C.ppm (gas ppm) |

spésifikasi (μm) |

pak-pakan (kg) |

| 316L | gas atomisasi |

≥5.0 | ≤600 | 15-50 | 5/25/50 | |

| 17-4PH | gas atomisasi |

≥5.0 | ≤600 | 15-50 | 5/25/50 | |

| M2 | gas atomisasi |

≥5.0 | ≤600 | 15-50 | 5/25/50 | |

| In718 | gas atomisasi |

≥4.7 | ≤600 | 15-50 | 5/25/50 | |

| In625 | gas atomisasi |

≥4.6 | ≤600 | 15-50 | 5/25/50 | |

| AISi12 | gas atomisasi |

≥5.0 | ≤500 | 15-50 | 5/25/50 | |

| AISi 10 Mg | gas atomisasi |

≥5.0 | ≤500 | 15-50 | 5/25/50 | |

aplikasi

Hak Cipta © Shanghai Knowhow Powder-Tech Co., Ltd. Sadaya hak disimpen - kabijakan privasi