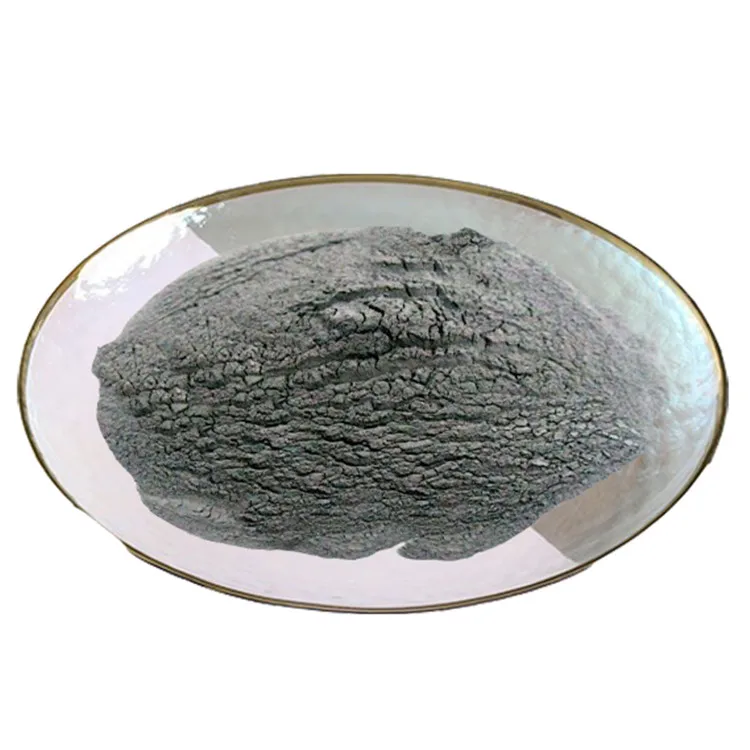

Ang Sponged Powder Iron, Ang Kapansin-pansing Sangkap Para sa Maraming Industriya

Ang lahat ng ito ay nagiging higit pa sa mga araw na ito habang ang sangkatauhan ay umasa sa bakal sa loob ng libu-libong taon - ang tibay, integridad at pagiging permanente ay bumangon mula sa kasaganaan nito. Ang sponged powder iron (SPI) ay isang versatile, maliwanag na bituin sa hanay ng mga uri ng bakal na malawakang ginagamit sa pagmamanupaktura, konstruksyon at automotive. Sa artikulong ito ToolStripMenuItem Sa Artikulo na Ito, Makakakuha Ka ng Panloob na Pananaw Kung Ano Ang SPI At Ang Mga Benepisyo Nito, Mga Kaso ng Paggamit, Mga Pagsusulong ng Teknolohiya at Mga Kakayahan.

SPI (water-atomized, gas-atomized at reduced/electrolytic iron powders): nagbibigay ng flexibility na nagbibigay sa end user ng hanay ng mga opsyon sa SPI na mapagpipilian depende sa mga pangangailangan ng application o antas ng performance na handang bayaran ng mga cup/customer. Mga kalamangan ng paggamit ng SPI sa produksyon

Pagkakapareho ng Sukat, Hugis at Kadalisayan: Ang SPI ay ginawa sa isang masusing paraan na nagsisiguro ng mahigpit na mga pamantayan pati na rin ang mga antas-human_READ +DFencodeURIComponent(b 216013235%%*/ Ang pagkakapare-parehong ito ay naghahatid ng lubos na mahuhulaan na mga resulta sa paggawa ng mga tagagawa.

6. Gayundin, ang SPI ay mas matipid para sa paggamit sa malakihang produksyon kaysa sa Iron Cost at size modification Syempre cost effective din.

Lakas at Timbang: Ang mga composite na nagmula sa SPI ay may kanais-nais na ratio ng lakas-sa-timbang at hindi nawawala ang liwanag habang nakakakuha ng mga mahihirap na katangian. Ang sinterability, weld- o brazeablity ng mga SPI ay maaaring maimpluwensyahan din ng mga mekanikal na katangian.

Ang SPI ay naka-deploy sa iba't ibang sektor sa industriya ng konstruksiyon halimbawa: Mga bubong, insulation sa ilalim ng mga heating floor at concrete reinforcement. Mga pakinabang ng paggamit ng SPI sa sektor ng gusali at konstruksyon

High-performance:Ang mga SPI na mas matatag na weight-to-strength transform banner material ay ginagamit para sa mas mahusay na pagkuha at pagbuo ng mga materyales kaya ang pagtatayo sa matataas na gusali na nakakabawas sa mga timbang nito.

Pinahusay na Paglaban sa Kaagnasan: Pinapataas ng Surface Pretreatment ang Rust, Salt at Moisture Anti-Corruption sa pamamagitan ng Pag-galvanize sa Proseso ng Substrate o Higit pang Advanced na SPI sa iba pang Machined Parts. Ito ang kalidad na ginagawang mahusay na magtayo sa malupit na kapaligiran at pangmatagalang pakikipag-ugnay sa mga kinakaing unti-unting bagay (Nasaklaw na namin ito dati).

Superior insulation - Ang mababang thermal conductivity ng SPI ay nagbibigay-daan upang magamit ito bilang isang insulating material. Gayunpaman, ang halaga nito para sa katangiang ito ay maaaring nasa paggamit ng isang insulated roofing panel o mga sistema ng pag-init at mga air duct.

Sa sektor ng automotive, ang SPI ay ginagamit para sa mga bahagi ng makina at transmission gear at brake disc. Ang Paggamit ng SPI sa Industriya ng Sasakyan

Pinahusay na pagganap at kahusayan - dahil sa walang kaparis na ratio ng strength-to-weight, ang SPI ay ang perpektong materyal para sa paggawa ng mga high-performance na bahagi ng automotive na nakakakuha ng mga pagtitipid sa timbang na pumasa sa mga benepisyo sa fuel-efficiency. Bilang karagdagan sa kakayahang makatiis ng init, ang Inconel ay sapat na malambot para sa mga turbocharger at mga sistema ng tambutso ng makina.

High-strength: Ang SPI ay nagtataglay ng parehong mahusay na sinterability at in-braze na kakayahan upang sumali sa iba pang uri ng mga materyales, hal. aluminyo, hindi kinakalawang na asero o ceramics na magkakasama Ang kakulangan ng pagsusuot ay ginagawang perpekto para sa mga automotive na bahagi na ininhinyero na tumakbo nang tuluyan sa field.

PAGKAKABISA SA GASTOS Ang pagsasaayos sa laki at hugis ng SPI ay maaaring magbigay-daan sa mga manufacturer na gumawa ng mga piyesa ng sasakyan sa paraang nakakatugon sa mga pamantayan sa disenyo at mahusay para sa mass production Ang kaginhawaan na ito ay lalong kapaki-pakinabang sa panahon ng paggawa ng mataas na dami, tulad ng paggawa ng maraming piyesa ng sasakyan.

Ang SPI ay nagiging laganap sa mga bagong application at isang malawak na spectrum ng mga operational environment dahil sa mga pagsulong na ginawa sa paglipas ng panahon pati na rin ang tumaas na pagganap, pagiging kumplikado. Ang ilan sa mga pagsulong sa Sa ngayon na teknolohiya ay ibinigay sa ibaba

Maaari itong magbigay ng mga application sa pag-print ng SPI 3D sa iba't ibang industriya, na nag-aalok ng mga bagong pagkakataon upang lumikha ng mga kumplikadong custom na bahagi. Ito ay totoo kahit na higit pa para sa mga industriya tulad ng aerospace, kung saan ang pagtitipid sa timbang at katatagan ay susi na ang kakayahang mag-print ng mga bahagi na may SPI ay maaaring mag-alok ng malaking benepisyo.

Alloying: Ang iba pang mga elementong idinagdag ay naglalaman ng haluang metal na SPI, paggamot ng solusyon na nagambala ng mga solidong solusyon sa tanso Sa paggawa nito, bumuo sila ng mga bagong haluang metal na may pinahusay na mekanikal, kaagnasan at mga katangian ng pagsusuot.

Surface Modification: Ginagawang posible ng mas mahusay na surface engineering para sa mga manufacturer na palawakin ang paggamit ng SPI sa pamamagitan ng pagbabago sa mga katangian nito. Sa iba pang halimbawang paraan tulad ng electroplating, nitriding at surface coatings ay maaari ding gamitin upang mapabuti ang pagkasira ng corrosion resistance o bawasan ang friction.

Ang Komposisyon at Mga Katangian ng Sponged Powder Iron - Talahanayan 1

Ang proseso ng produksyon, nagreresulta sa laki at hugis ng mga particle pati na rin ang ibabaw na lugar ay humantong sa ilang mga katangian ng husay tungkol sa komposisyon ng SPI. Ang SPI ay naglalaman ng 98 wt% o higit pa ng bakal kasama ng maliit na halaga ng carbon, sulfur at iba pang elemento. Ang anisotropy ng ari-arian ng SPI ay inilalarawan bilang mataas na densidad, mababang thermal yang na mga kalasag na nanoelectronicsMula sa mga pagsukat ng paglaban sa kuryente na may napaka-modulas na pagsukat na nagbibigay ng mga resulta ng conductance na nagpapakita at natagpuang nagtataglay ng 23% na higit pa kumpara sa ginustong sariling domain. gamitin sa wave energy oscillatory motion dahil diyan ang mga microwave na nauugnay kasama ng mga nanoparticle ay nabawasan ang pagsusubo ng labis na katumbas Sa mga tuntunin pagiging epektibo ng mga katangian.

Sa madaling sabi, ang sponged powder iron ay isang multipurpose material na ginagamit sa iba't ibang larangan tulad ng field ng paggawa; pagtatayo ng mga istruktura at industriya ng sasakyan. Applications & Development SPI ay isang magandang bagay para sa paggawa ng ganitong uri ng bahagi na may mataas na lakas ng problema at gayundin sa mga aspeto tulad ng ekonomiya. Ang teknolohiya ng SPI ay naisip na lalago pa sa flexibility habang magpapatuloy ang pananaliksik at pag-unlad.

ay akreditado ISO9001, SGS at REACH. Ang KPT ay isang provincial powder metallurgy research center, ay may patuloy na sponged powder iron kasama ang mga unibersidad sa pananaliksik na institusyon. Nag-aalok kami sa iyo ng single-stop na serbisyo hanggang sa masiyahan.

pambihirang serbisyo sa paghahatid at pagpapadala. Ini-export namin ang aming mga kalakal sa higit sa 30 sponged powder ironna kinabibilangan ng North America, South America Asia.

Ang pangunahing aktibidad ay ang paggawa ng mga pulbos na metal. nag-aalok ng iba't ibang uri ng mga produkto tulad ng water atomized powders, sponge Iron hydrogen reduced sponge powder mababa ang maliwanag na densidad high-alloy powder superfine powders kabilang ang hindi kinakalawang na asero, sponged powder ironpowders pati na rin ang tansong pulbos.

Ang KPT Company ay may taunang kapasidad ng produksyon na 200000 tonelada at may sponge iron ang sponged powder ironof atomized powder. Ito ay pinaka-technologically advanced, komprehensibong pinakamalaking powder production company China.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. Lahat ng Karapatan - Pribadong Patakaran