Hom Lub Npe: KPT

KPT txaus siab los qhia txog nws cov hydrogen uas yog daim txhuam cev uas yog cov hmoov zoo tshaj plaws rau kev sib txhuam, tshwj xeeb tshaj yog tsim los ua kom tau raws li qhov xav tau ntawm kev lag luam thiab cov ntawv thov uas xav tau lub zog ua piv txwv, kav ntev, thiab kev ntseeg tau. Peb cov khoom lag luam yog qhov tseem ceeb vim tias cov txheej txheem tsim khoom hauv lub xeev thiab cov kev tswj xyuas zoo tshaj plaws, uas yuav pab kom paub tseeb tias txhua pawg peb tsim ua kom txaus siab rau kev lag luam uas yuav tsum tau ua siab tshaj thiab cov neeg siv khoom lub hom phiaj.

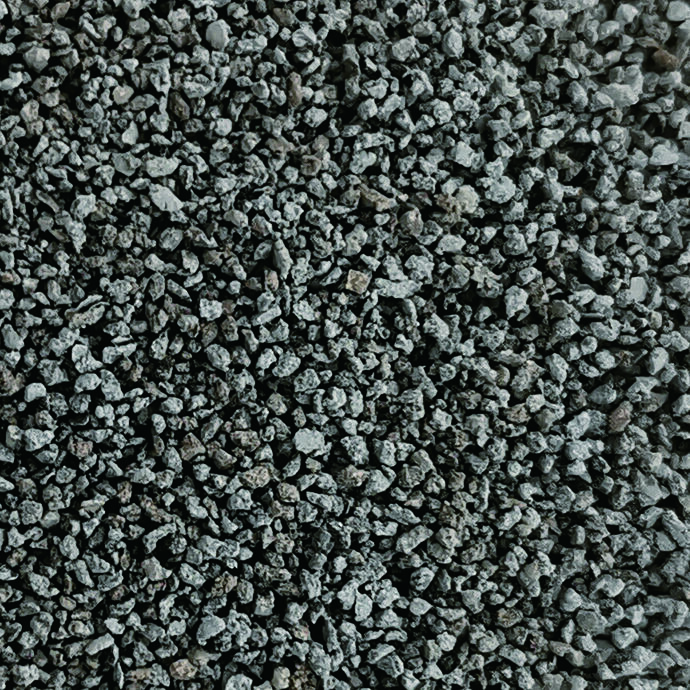

Peb lub Hoobkas tsim tawm hydrogen sponge txo cov hmoov hlau rau kev sib txhuam yog tsuas yog cov khoom siv no yeej muaj ntau yam pom kev siv dav hauv ntau qhov kev lag luam. Raws li ib qho piv txwv, nws yog zoo meej rau pom nyob rau hauv kev lag luam uas yog automotive nws yog ua hauj lwm nyob rau hauv lub tsim ntawm braking system pads, clutch phaj, raws li zoo raws li lwm yam kev sib txhuam Cheebtsam. Nws kuj tau siv dav hauv cov mining, agrochemicals, thiab cov tuam txhab tsim kho.

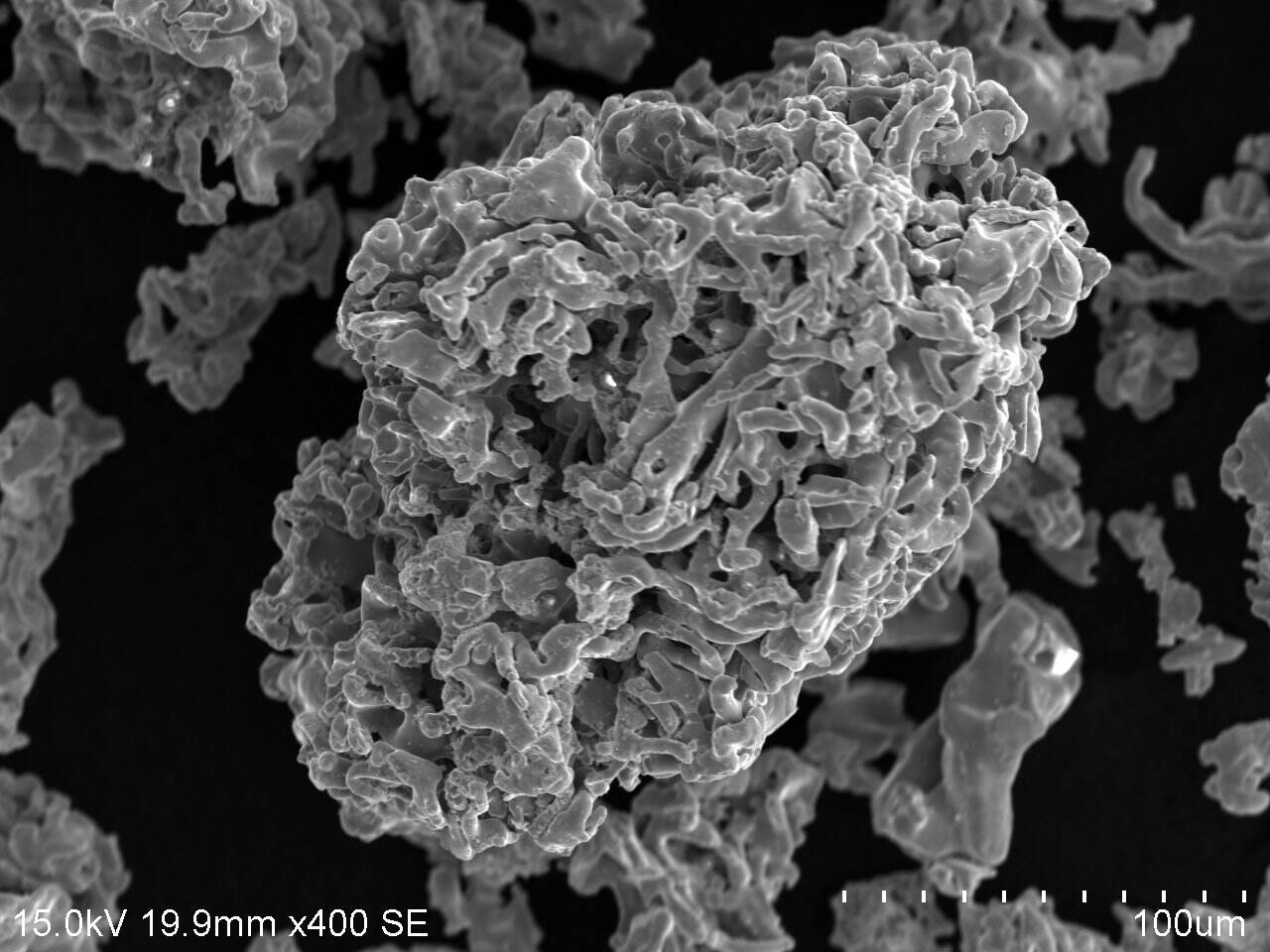

Ntawm ntau tus yuam sij saum toj kawg nkaus ntawm peb cov hydrogen sponge-txo hlau hmoov rau kev sib txhuam yog nws qhov zoo tshaj plaws uas yog vim muaj cov khoom tshwj xeeb ntawm cov khoom siv rov ua dua tshiab uas peb siv. Peb siv cov ntaub ntawv siab purity, ua kom cov khoom no yog qhov kawg tsis muaj impurities nrog rau lwm yam kab mob uas yuav cuam tshuam rau nws qhov kev ua tau zoo. Tsis tas li ntawd, peb cov txheej txheem tsim khoom suav nrog kev saib xyuas uas yog kev sim ua tib zoo thiab cov txheej txheem tswj kom zoo, suav nrog kev tshuaj xyuas nruj kom lav cov khoom kawg ua tiav cov kev xav tau zoo tshaj plaws.

Peb hydrogen daim txhuam cev them nyiaj hlau hmoov rau kev sib txhuam yog ib yam khoom uas muaj txiaj ntsig zoo muab cov khoom siv zoo xws li lub zog tensile siab, hardness, thiab durability. Qhov no tiag tiag yog tag nrho cov txiaj ntsig ntawm cov khoom siv hlau tshwj xeeb ntawm peb cov khoom, uas xav tau los tsim cov khoom siv uas yuav tiv taus qib siab ntawm kev puas tsuaj lossis kev ntxhov siab.

Kev lees paub uas suav nrog thaum koj nkag siab tias lawv muaj cov khoom lag luam zoo uas lawv feem ntau ua raws li ntawm KPT, peb pom tias kev ua haujlwm ntev thiab kev ntseeg tau yog qhov tsim nyog ntawm cov khoom lag luam uas piav qhia vim li cas peb thiaj li muab peb cov neeg siv khoom.

Peb cov khoom tuaj yeem yuav hauv ntau qhov sib txawv, ua rau nws zoo tagnrho rau kev siv sib txawv thiab kev lag luam. Peb ua haujlwm ze nrog koj cov neeg siv khoom kom ntseeg tau tias lawv yuav nkag mus rau cov khoom uas muaj ntau yam suits uas muaj txiaj ntsig zoo thiab xav tau.

Tshuaj khoom | Tsev | specification | |||

TSW 80 | |||||

Min | Max | Min | Max | ||

H2- Loss | % | 0.4 | 1.4 | 0.5 | 1.3 |

Acid insolubility | % | 0.6 | 0.5 | ||

Fe yog Base | % | ||||

Lub Cev Lub Cev | |||||

Pom pom qhov ntom ntom | g / cm3 | 1.6 | 2.2 | 2.3 | 2.5 |

Particle loj faib | |||||

+80 mesh | % | 1 | 0.1 | ||

+ 100-80 mesh | % | 10 | 1 | ||

+ 140-100 mesh | % | 7 | 27 | 6.5 | 17.5 |

+ 200-140 mesh | % | 18.5 | 30.5 | 17 | 31 |

+ 325-200 mesh | % | 23.5 | 35.5 | 25.5 | 40.5 |

-325 mesh | % | 11.5 | 35.5 | 19 | 41 |

hlau hmoov | Tshuaj khoom | Tsev | Tus nqi zoo (%) | specification | ||||||

Min | Max | |||||||||

ZTR 12 | C | % | 0.012 | 0.03 | ||||||

Mn | % | 0.35 | 0.65 | |||||||

P | % | 0.08 | 0.012 | |||||||

S | % | 0.009 | 0.05 | |||||||

HL | % | 0.5 | 2.5 | |||||||

Acid insolubility | % | 0.33 | 0.4 | |||||||

TFe | % | 98.1 | 97 | 98.5 | ||||||

ZTR 80 | HL | % | 0.4 | 1.4 | ||||||

Acid insolubility | % | 0.4 | ||||||||

Fe yog Base | % | |||||||||

Lub Cev Lub Cev | ||||||||||

ZTR 12 | Pom pom qhov ntom ntom | g / cm3 | 1.36 | 1 | 1.5 | |||||

Ntsuab ceev 212MPA | g / cm3 | 4.95 | 4.6 | 5 | ||||||

ZTR 80 | Pom pom qhov ntom ntom | g / cm3 | 1 | 1.5 | ||||||

Ntsuab ceev | g / cm3 | 5.8 | 6.1 | |||||||

Copyright © Shanghai Knowhow Powder-Tech Co., Ltd. All Rights Reserved - Tsis pub twg paub Txoj cai