Hom Lub Npe: KPT

KPT Welding Powder Iron Powder tej zaum yuav yog qhov vuam qhov no yog qhov zoo heev uas tsim cov welds uas zoo tshaj plaws yuav ua tau ob qho tib si ruaj thiab kav ntev. Qhov no system no yeej muaj ntau yam yuav tsum-muaj rau welders nyob rau hauv tsuas yog hais txog tej kev lag luam tab tom nrhiav rau ib tug ncaj ncees, kev khwv nyiaj txiag, thiab kev daws qhov no yeej muaj tseeb raws li nws cov kev cai vuam.

KPT Welding Powder Iron Powder yog tsim los ntawm cov hmoov hlau zoo tshaj plaws no yog ua tib zoo xaiv thiab txaus siab ua vuam qhov no yeej paub tseeb tias yog tas li. Qhov no muaj cov hmoov no yog qhov loj me uas yog qhov zoo rau qib purity saum toj kawg nkaus, ua kom cov txheej txheem du thiab vuam qhov no yeej ua tau zoo.

Muaj tseeb tiag, ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev xaiv KPT Welding Powder Iron Powder yog nws qhov tso tawm qhov no yuav yog tus nqi ntau dua yog li koj tuaj yeem yooj yim rau vuam ntau dua hauv lub sijhawm sai dua. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog nyob rau hauv high-volume manufacturing puag ncig qhov twg lub sij hawm yog los ntawm cov essence. Welders yuav ua daim ntawv cog lus uas tej zaum yuav yog cov pob txha uas muaj zog raug yuam kom mob siab rau qee lub sij hawm qhov no yeej yog qhov ntau dhau ntawm lawv hnub ua haujlwm, los pab koj daws cov haujlwm loj sai thiab ua tau zoo.

KPT Welding Powder Iron Powder kuj tsim cov pa luam yeeb qhov no yog qhov ua rau muaj qhov tsawg kawg nkaus ntawm cov txheej txheem vuam, uas txhais tau hais tias nws yog ib qho tshuaj ntxuav thiab ntau ntxiv qhov no yeej ib puag ncig tus phooj ywg. Qhov no tuaj yeem tau txais txiaj ntsig zoo hauv qhov chaw txwv lossis tej zaum nyob rau hauv qhov xwm txheej uas cov cua ntws tau ruaj khov. Tsis tas li ntawd, nws yuav ua rau nws muaj peev xwm pab ua kom qhov chaw vuam huv si, muab qhov chaw ua haujlwm nyab xeeb rau ntau qhov chaw.

Lwm qhov laj thawj tseem ceeb rau KPT Welding Powder Iron Powder yog kom muaj nuj nqis rau nws cov kev sib raug zoo ntawm cov hlau, nrog rau cov pa roj carbon steel, hlau, thiab cov hlau tsis tshua muaj zog. Qhov no tso cai rau cov neeg siv vuam siv lub vuam qhov no yog cov kev daws teeb meem uas yog ib qho kev siv ntau yam, ua rau nws muaj ntau yam thiab cov cuab yeej siv nyiaj txiag muaj nyob hauv txhua qhov kev teeb tsa vuam.

Vuam hmoovRaws li cov khoom tseem ceeb hauv kev tsim cov khoom siv vuam ntau, cov yam ntxwv ntawm cov hmoov hlau feem ntau muaj kev cuam tshuam ncaj qha rau ob qho tib si vuam thiab qhov kawg vuam hlau zoo. Pab txhim kho cov yam ntxwv thiab kev ua tau zoo ntawm cov electrodes npog nrog rau cov xov hlau flux-cored thiab hlau-cored.Peb cov qib sponge yog qhov txawv ntawm qhov loj me me, cov tshuaj muaj pes tsawg leeg, particle morphology thiab pom tseeb ntom ntom.Xaiv hlau hmoov nrog cov yam ntxwv tsim nyog rau daim ntawv thov. yuav ua rau kev txhim kho efficiency thiab tag nrho cov vuam kev ua tau zoo.

Specification ntawm Sponge hlau hmoov |

|

|

|

|

|

Chemical Properties (%) | Tsev | |

| TSW 40.37 |

|

|

|

|

|

| Min | Max | Min | Max |

|

|

|

C | % |

| 0.06 |

| 0.06 |

|

|

|

|

|

Si | % |

| 0.12 |

| 0.12 |

|

|

|

|

|

Mn | % |

| 0.2 |

| 0.2 |

|

|

|

|

|

P | % |

| 0.005 |

| 0.005 |

|

|

|

|

|

S | % |

| 0.01 |

| 0.01 |

|

|

|

|

|

HL | % |

| 0.8 |

| 0.8 |

|

|

|

|

|

V | % |

|

|

| 0.1 |

|

|

|

|

|

TFe | % | 98 |

|

|

|

|

|

|

|

|

Fe |

|

|

| 98 |

|

|

|

|

|

|

Lub Cev Lub Cev |

|

|

|

|

|

|

Pom pom qhov ntom ntom | g / cm3 | 2.75 | 3 | 3.6 | 3 |

|

|

|

|

|

Particle loj faib (%) |

|

|

|

|

|

|

+500 ua | % |

| 0 |

| 0 |

|

|

|

|

|

+355 ua | % |

| 5 | 0 | 12 |

|

|

|

|

|

+250 ua | % | 2 | 20 | 10 | 40 |

|

|

|

|

|

+150 ua | % | 40 | 70 | 50 | 80 |

|

|

|

|

|

+75 ua | % | 90 | 100 | 85 | 100 |

|

|

|

|

|

kev pab cuam:

• Ntau yam ntawm cov hmoov hlau uas tsim los rau kev siv vuam

• Nqaim specifications

• Cov khoom siv tshuaj lom neeg thiab lub cev sib xws

• Tsawg theem ntawm impurities

• Cov kev daws teeb meem zoo logistics thiab kev ntim khoom ntse

Cov qib rau kev siv vuam xws li40.29, 40.35, 40.37, 100.25, 1%FeB. peb tuaj yeem kho cov hmoov hlau los ntawm cov neeg yuav khoom.

HAIS TXOG:

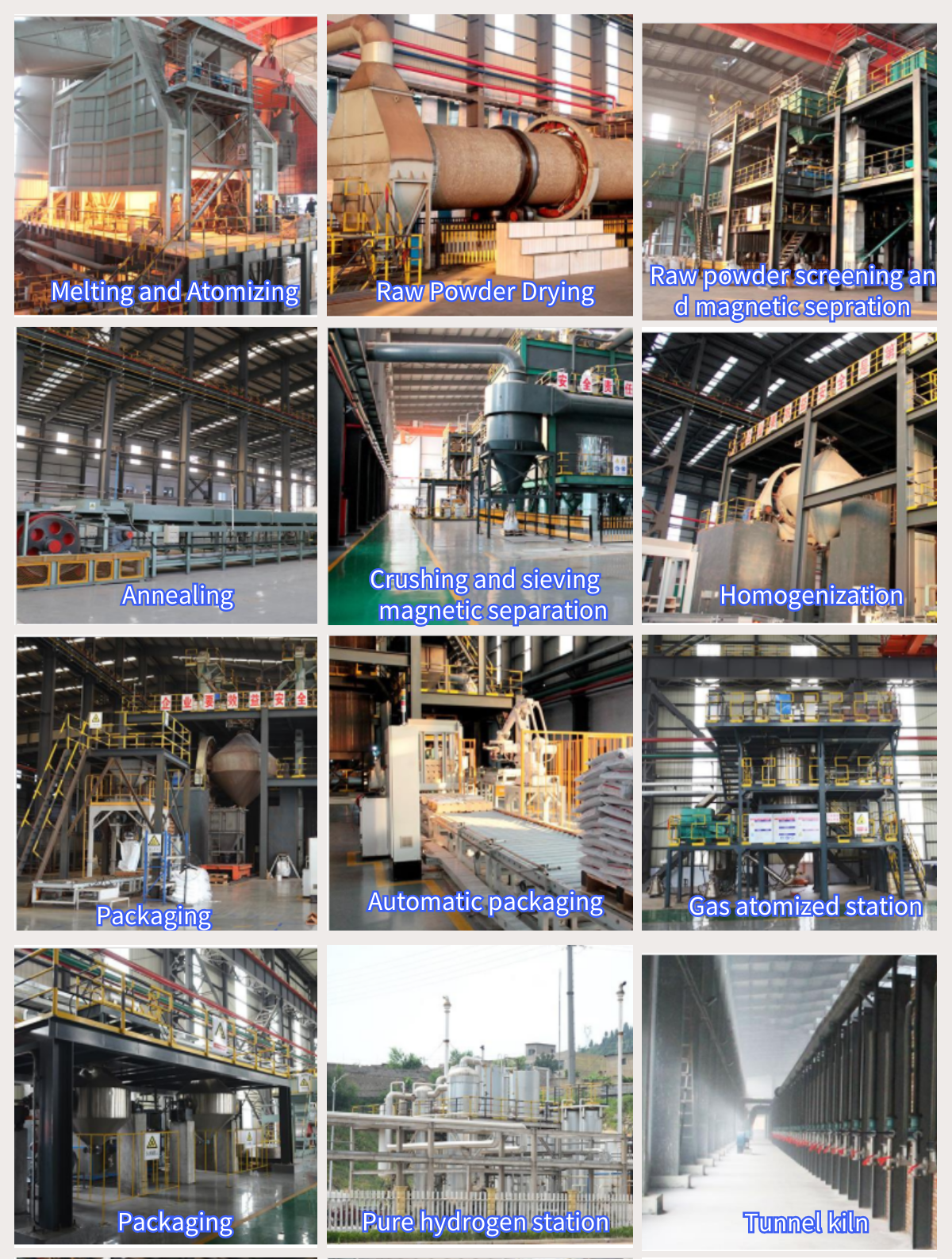

Lub Hoobkas ntawm KPT Co., Ltd. tau tsim muaj nyob rau hauv 1987, tom qab 30 xyoo ntawm txoj kev loj hlob, lub tuam txhab tau dhau los ua ib tug niaj hnub loj nplai thiab cog lus hmoov chaw tsim tshuaj paus nrog advanced technology thiab sophisticated ua cov cuab yeej. Lub tuam txhab yog lub hauv paus ntawm lub teb chaws high-tech kev tshawb fawb thiab kev loj hlob kev pab cuam (863Program) industrialization ua tau zoo; lub caj qaum kev lag luam rau cov khoom siv tshiab industrialization puag;

Lub tuam txhab muaj peev xwm tsim tau txhua xyoo tau mus txog 200,000 metric tons. Lub tuam txhab muaj ob qho tib si sponge hlau thiab atomized hmoov ntau lawm kab (dej atomized, dej & vapor ua ke atomized thiab inert gas atomized), yog tam sim no qhov loj tshaj plaws thiab ntau yam ua tiav nrog nplua zoo hmoov ntau lawm enterprise. Cov khoom tseem ceeb muaj xws li daim txhuam cev hlau hmoov, atomized hmoov, stainless hlau hmoov thiab hlau mos magnetic hmoov. Cov khoom tau txais txiaj ntsig raws li "Shandong nto moo hom". Tag nrho cov khoom raug lees paub rau IS09001 zoo system. Cov khoom siv dav siv hauv tsheb. maus taus, tsev neeg thov, vuam, tshuaj lom neeg kev lag luam, thiab lwm yam. Kev lag luam hauv tsev tau nce mus txog 25%. Cov khoom muag tau muag zoo hauv 25 lub xeev thiab lub nroog ntawm Tuam Tshoj thiab xa tawm mus rau Nyiv, Kaus Lim Kauslim, Nyab Laj, Thaib thiab lwm lub tebchaws.

Lub sijhawm tshiab, KPT Co., Ltd. yuav muab cov neeg siv khoom nrog cov khoom lag luam zoo dua thiab cov kev pabcuam kev lag luam. Lub tuam txhab yuav txuas ntxiv mus rau pem hauv ntej nrog lub hom phiaj ntawm "tsim kom muaj kev sib tw thoob ntiaj teb cov khoom siv hmoov".

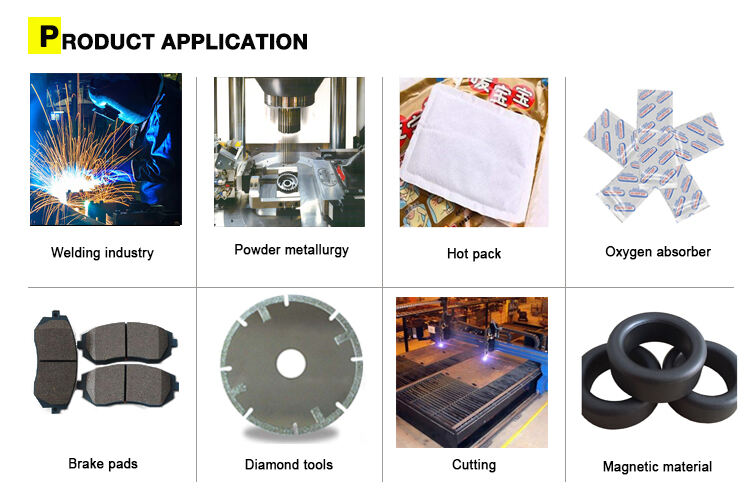

Hlau hmoov rau vuam cov ntaub ntawv muaj xws li:

Txo hlau hmoov 40 mesh, radized hlau pwoder 100 mesh, atomized hlau hmoov 40 mesh thiab lwm yam.

Hlau hmoov rau hmoov metallurgy incloudes:

Daim txhuam cev hlau hmoov 80 mesh, sponge hlau pwoder 100 mesh, atomized hlau pwoder 100 mesh thiab lwm yam.

Kev siv cov hmoov hlau muaj xws li: vuam electrode, hmoov metallurgy, cov ntaub ntawv sib txhuam, kev kho dej, cov me nyuam sov, nplaim taws txiav, additives, deoxidizer, pob zeb diamond cov cuab yeej, cov khoom sib nqus, thiab lwm yam.

Koj tuaj yeem xaj raws li peb cov khoom specification, peb kuj tuaj yeem tsim raws li koj qhov specification.

Thov nug kuv rau kev hais lus

2. Q: Koj lub Hoobkas nyob qhov twg? Kuv tuaj yeem mus saib tau li cas?

A: Peb lub Hoobkas nyob hauv Laiwu koog tsev kawm ntawv, Jinan nroog, Shandong xeev, Suav. Koj tuaj yeem tuaj rau Shanghai ua ntej thiab hloov mus rau peb lub Hoobkas nrog peb, lossis koj tuaj yeem ya mus rau Jinan nroog thiab peb yuav tuaj tos koj ntawm tshav dav hlau lossis chaw nres tsheb ciav hlau ceev.

3. Q: Kuv yuav them li cas rau kuv daim ntawv xaj khoom?

A: TT thiab LC

4. Q: Kuv tuaj yeem tau txais qee qhov qauv thiab yuav siv sijhawm ntev npaum li cas?

A: Rau cov qauv me me, nws yog dawb, tab sis huab cua freight yog sau los yog them peb tus nqi ua ntej, peb feem ntau siv International Express, thiab peb yuav xa tuaj rau koj tom qab tau txais koj cov nqi.

5. Q: Koj puas muaj kev tswj xyuas zoo?

A: Peb muaj kev tswj xyuas zoo rau txhua kauj ruam ntawm kev tswj cov txheej txheem, thiab peb muaj kev tswj hwm los ntawm cov khoom siv raw mus rau cov khoom tiav. Peb muaj ntau daim ntawv pov thawj ntawm QA THIAB QC xws li ISO daim ntawv pov thawj thiab IATF16949.

6. Q: Qhov kev txiav txim yam tsawg kawg nkaus yog dab tsi?

A: 100 grams.

7. Q: Txog Nqe:

A: Tus nqi yog sib tham. Nws tuaj yeem hloov pauv raws li koj qhov ntau lossis pob. Thaum koj ua qhov kev nug, thov qhia rau peb paub qhov ntau npaum li cas koj xav tau. Qee cov khoom peb muaj nyob rau hauv Tshuag.

Nco ntsoov koj cov lus nug yuav teb rau hauv 24 teev nrog peb cov lus qhia tshaj lij.

Txais tos tiv tauj peb los ntawm Email, Wechat, Skype, WhatsApp, lossis hu xov tooj.