INTRODUCTION

Thermal spraying technology is widely used in pre-protection and remanufacturing industries. The thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. Coating materials include metals, alloys, ceramics, plastics and composites. They are mostly fed in powder form. Thermal Spray Powders are used in a variety of applications including Plasma Transfer Arc (PTA), Spray and Fuse, High Velocity Oxy-Fuel (HVOF), Laser Additive (3D print).

Typically, these applications require hardness, morphology and a particular particle size distribution. The hardness of powder are between HRC 15 and 70. Particle size distribution can be adjusted according to customer needs.

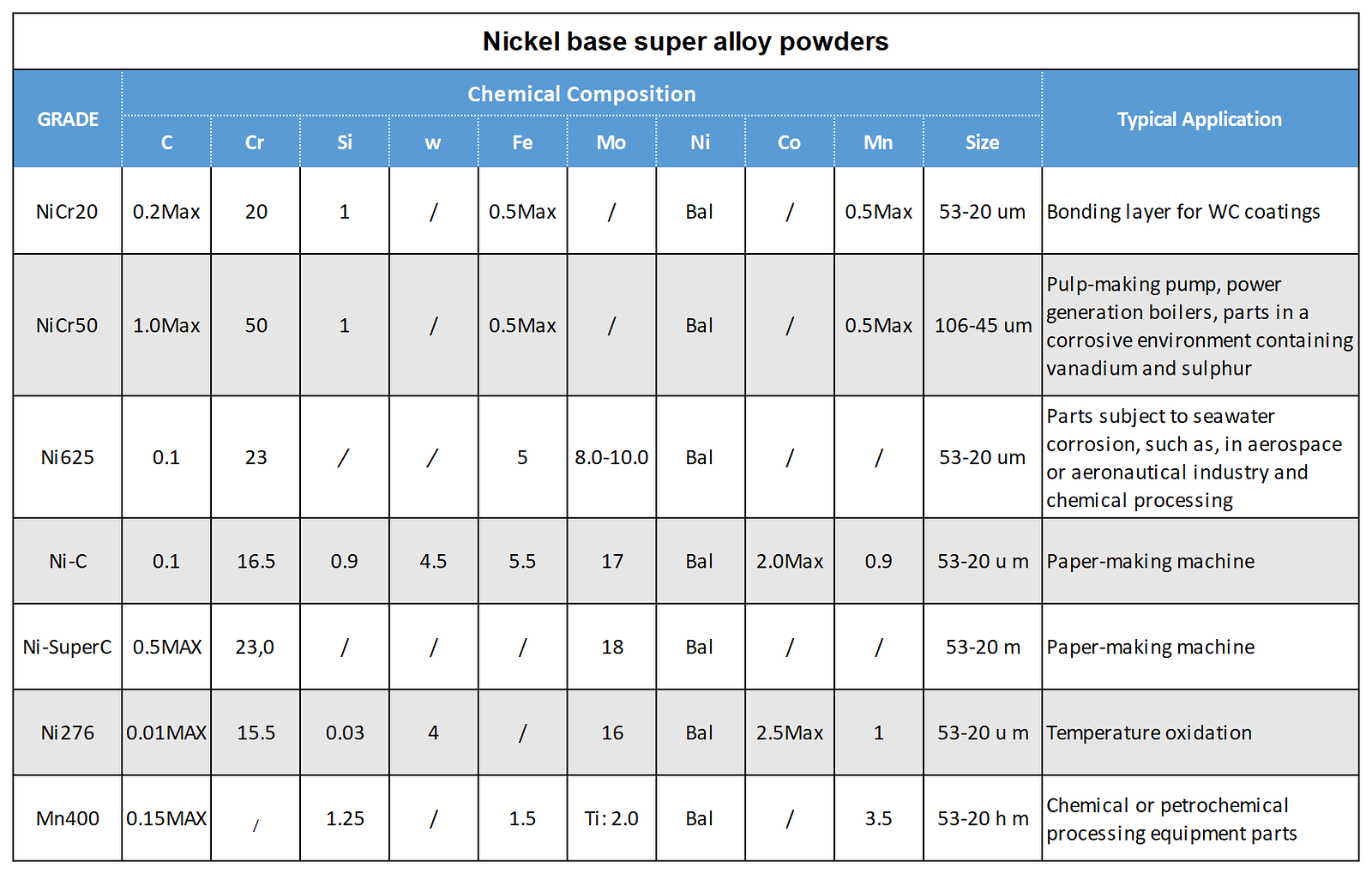

Nickel base alloy powder

These powders include Ni-B-Si Ni-Cr-B-Si, Ni-Cr-B-Si-P, Ni- Cr- B- Si-Cu-Mo, Ni-Cr-B-Si-W, Ni-Cr, and Ni-Cu alloys. They are used for applications with great corrosion resistance or oxidation resistance. Under 500°C, they have excellent low-stress abrasion and adhesive wear resistance. These powders can be applied into a variety of processes, such as, oxyacetylene spraying or overlaying. HVOF/HFAF spraying. Plasma transferred are (PTA) overlaying, plasma spraying, laser overlaying, induction melting overlaying, centrifugal casting, 3D printing and powder metallurgical processing. Key applications include valve gates,

ball valve surface, valve seats, pistons, plastics extruder screws, glass molds, steel mill rolls, wire drawing rolls, oil pumping shafts, fan blades, screw conveyors and tungsten carbide tools.

Specification of Cobalt base alloy powder

PRODUCT PACKING

25kg/barrel, 50kg/barrel, the package can be customized by buyer’s requirements.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy