KPT

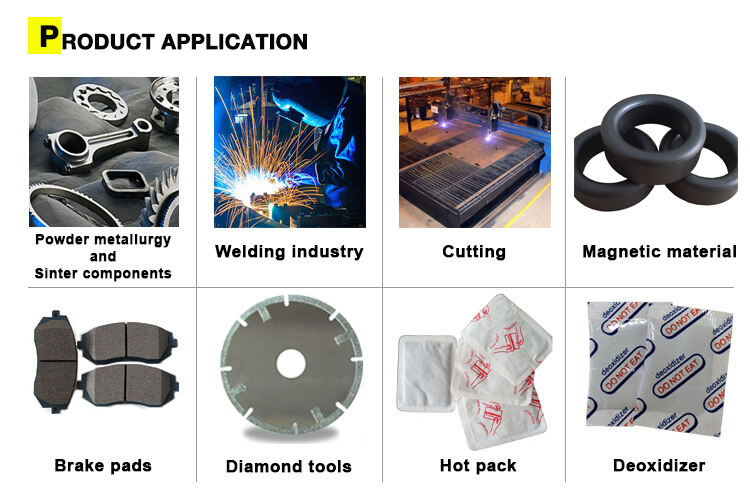

Ferro Manganese Powder Manufacturers for Welding Industry for the production of welding rods and wires. KPT is a leading brand of Ferro manganese powder manufacturers and has been a preferred choice for customers worldwide for many years. The powder is made by combining manganese and iron, which results in a superior quality product that is used extensively in the welding industry.

Manufactured utilizing the technology that is latest and quality control measures, ensuring the highest degrees of purity, consistency, and usability. The powder is produced under strict quality control conditions, making certain only the quality Ferro that is most beneficial manganese powders is sent to customers.

Commonly utilized in the welding industry to enhance the durability and strength associated with metal that is welded. KPT Ferro manganese powder is an ingredient that is important welding as it provides exceptional resistance to corrosion and has now high melting and boiling points. The powder is also employed for the production of iron and steel alloys, which are used in the automotive, construction, and aerospace companies.

For sale in a variety of particle sizes, which range from fine to coarse. Clients can chose the most particle that is suitable, according to their welding requirements. The powder is loaded and delivered to clients in top-notch packaging, ensuring safe and transport is efficient.

Furthermore, KPT has an extremely knowledgeable group that is technical is always open to help clients making use of their welding requirements. The group provides support in the use of the Ferro manganese powder, welding techniques, and troubleshooting. This helps to ensure that customers get performance that is optimal using the KPT Ferro manganese powder to produce high-quality welded structures and parts.

Call KPT today to more about Ferro Manganese Powder Manufacturers for Welding Industry.

Welding electrodes

Welding wire

Cored wire

Surface coating

Foundry additive

Hardfacing

Alloy steel manufacturing

Grade | Chemical composition(%) | Particle size distribution(%) | ||||||

Mn | C | Si | P | S | ||||

High grade | Middle grade | High grade | Middle grade | |||||

FeMn84C0.7 | 80-87 | ≤0.7 | ≤1.0 | ≤2.0 | ≤0.20 | ≤0.30 | ≤0.02 | 40mesh,50mesh,60mesh,80mesh customized |

FeMn82C1.0 | 78-85 | ≤1.0 | ≤1.5 | ≤2.0 | ≤0.20 | ≤0.35 | ≤0.03 | 40mesh,50mesh,60mesh,80mesh customized |

FeMn82C1.5 | 78-85 | ≤1.5 | ≤1.5 | ≤2.0 | ≤0.20 | ≤0.35 | ≤0.03 | 40mesh,50mesh,60mesh,80mesh customized |

FeMn78C2.0 | 75-82 | ≤2.0 | ≤1.5 | ≤2.5 | ≤0.20 | ≤0.40 | ≤0.03 | 40mesh,50mesh,60mesh,80mesh customized |

FeMn68C7.0 | 65-72 | ≤7.0 | ≤2.5 | ≤4.5 | ≤0.25 | ≤0.40 | ≤0.03 | 40mesh,50mesh,60mesh,80mesh customized |

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy