Brand: KPT

KPT is proud to introduce its hydrogen that is sponge that is top-notch powder for friction, particularly developed to meet the demanding needs of industries and applications that want exemplary power, durability, and reliability. Our product is basically because state-of-the-art manufacturing processes and advanced quality control measures, which helps to make sure that every batch we create satisfies the industry requirements being highest and customer objectives.

Our factory-produced hydrogen sponge reduced iron powder for friction is simply a material this is certainly versatile finds wide applications in several industries. As an example, it is perfect for found in the industry that is automotive it is employed in the manufacture of braking system pads, clutch plates, as well as other friction components. It's also widely used inside the mining, agrochemicals, and construction companies.

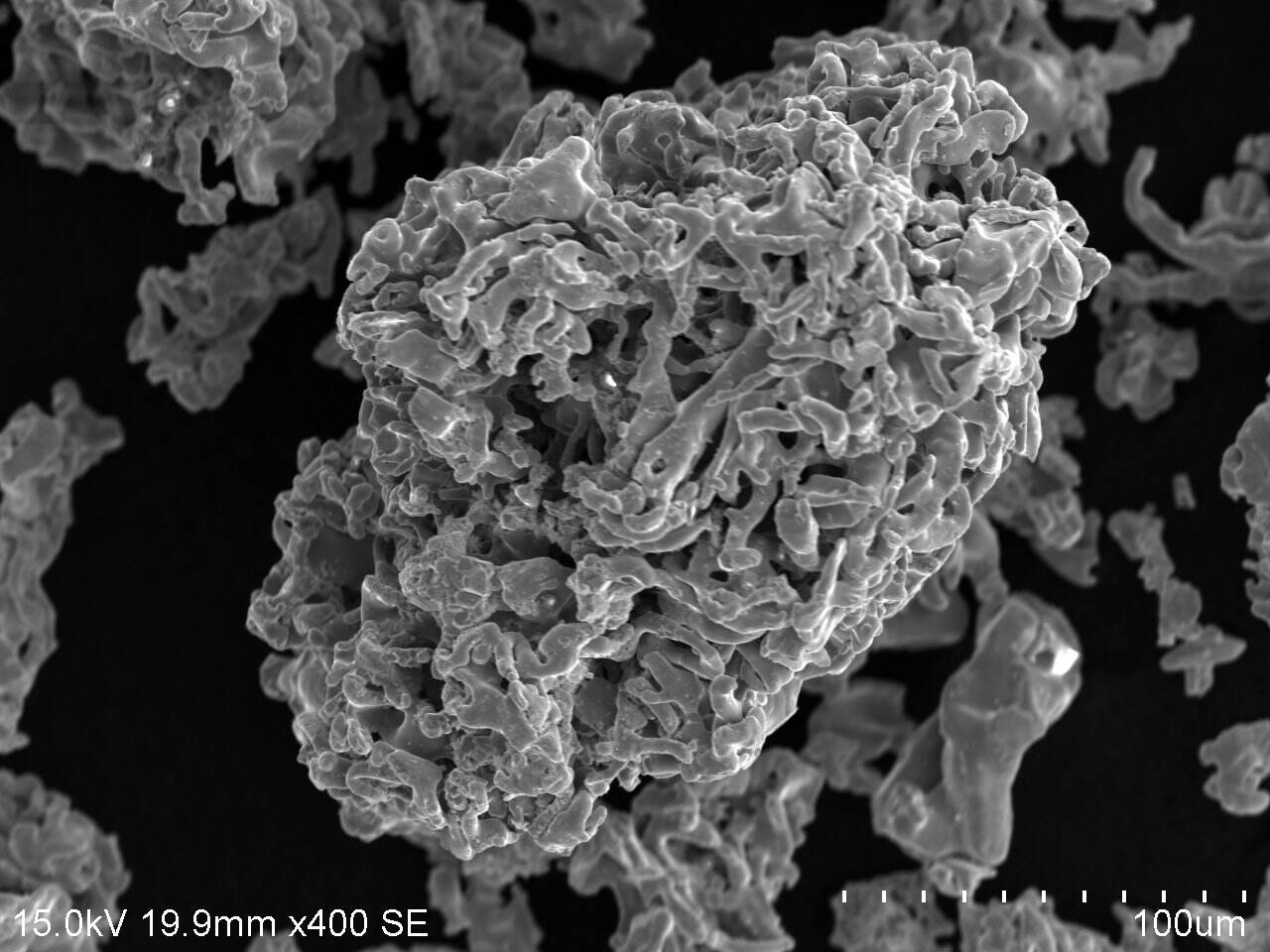

Among the many keys top features of our hydrogen sponge-reduced iron powder for friction is its quality this is certainly superior that is due to the unique properties of this recyclables we use. We utilize materials being high in purity, making sure the item this is certainly final free of impurities as well as other contaminants that may influence its performance. Furthermore, our production procedure involves monitoring that is testing that is careful and quality control procedures, including rigorous inspections to guarantee the final item satisfies the best requirements.

Our hydrogen sponge paid down iron powder for friction is truly an item that is very efficient delivers exemplary mechanical properties such as high tensile strength, hardness, and durability. This really is as a total result of exceptional metallurgical properties of our item, which are needed for creating components which will withstand high degrees of abrasion or anxiety.

The reassurance that is included with once you understand they have an excellent product they are often based on at KPT, we observe that durability and reliability are necessary facets in relation to materials that are commercial which explains why we aim to offer our consumers.

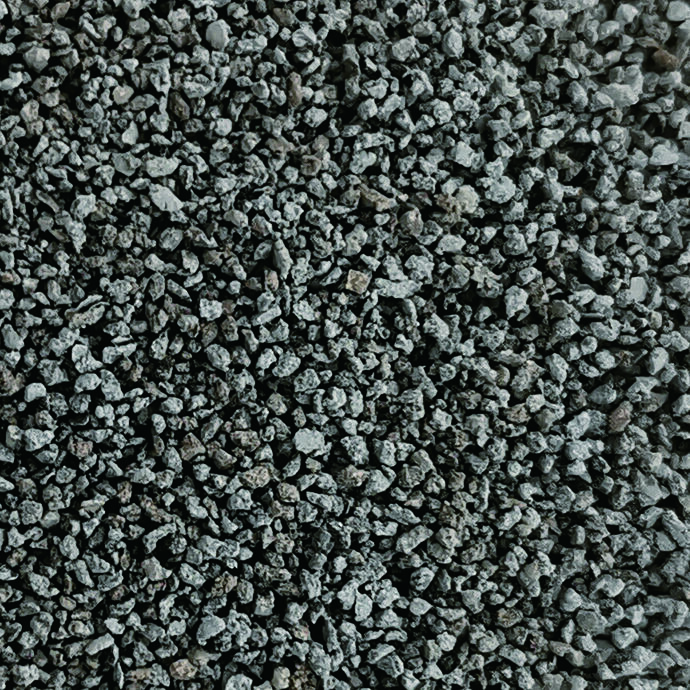

Our item can be purchased in different particle sizes, rendering it ideal for different applications and industries. We work closely with your clients to ensure they will have access to the item that a lot of suits that are useful needs and demands.

Chemical Properties | Unit | Specification | |||

ZTLD80 | |||||

Min | Max | Min | Max | ||

H2-Loss | % | 0.4 | 1.4 | 0.5 | 1.3 |

Acid insolubility | % | 0.6 | 0.5 | ||

Fe is Base | % | ||||

Physical Properties | |||||

Apparent density | g/cm3 | 1.6 | 2.2 | 2.3 | 2.5 |

Particle size distribution | |||||

+80 mesh | % | 1 | 0.1 | ||

+100-80 mesh | % | 10 | 1 | ||

+140-100 mesh | % | 7 | 27 | 6.5 | 17.5 |

+200-140 mesh | % | 18.5 | 30.5 | 17 | 31 |

+325-200 mesh | % | 23.5 | 35.5 | 25.5 | 40.5 |

-325 mesh | % | 11.5 | 35.5 | 19 | 41 |

iron powder | Chemical Properties | Unit | Typical values(%) | Specification | ||||||

Min | Max | |||||||||

ZTR12 | C | % | 0.012 | 0.03 | ||||||

Mn | % | 0.35 | 0.65 | |||||||

P | % | 0.08 | 0.012 | |||||||

S | % | 0.009 | 0.05 | |||||||

HL | % | 0.5 | 2.5 | |||||||

Acid insolubility | % | 0.33 | 0.4 | |||||||

TFe | % | 98.1 | 97 | 98.5 | ||||||

ZTR80 | HL | % | 0.4 | 1.4 | ||||||

Acid insolubility | % | 0.4 | ||||||||

Fe is Base | % | |||||||||

Physical Properties | ||||||||||

ZTR12 | Apparent density | g/cm3 | 1.36 | 1 | 1.5 | |||||

Green density 212MPA | g/cm3 | 4.95 | 4.6 | 5 | ||||||

ZTR80 | Apparent density | g/cm3 | 1 | 1.5 | ||||||

Green density | g/cm3 | 5.8 | 6.1 | |||||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy