Brand: KPT

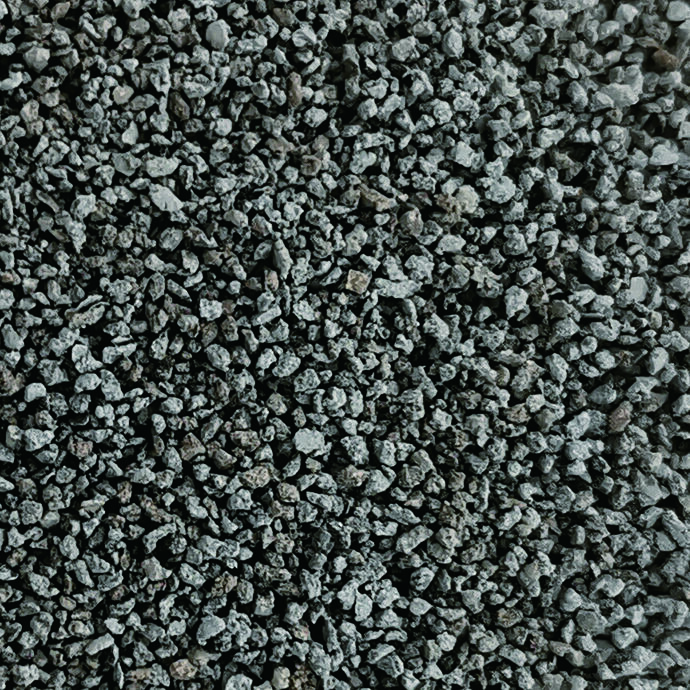

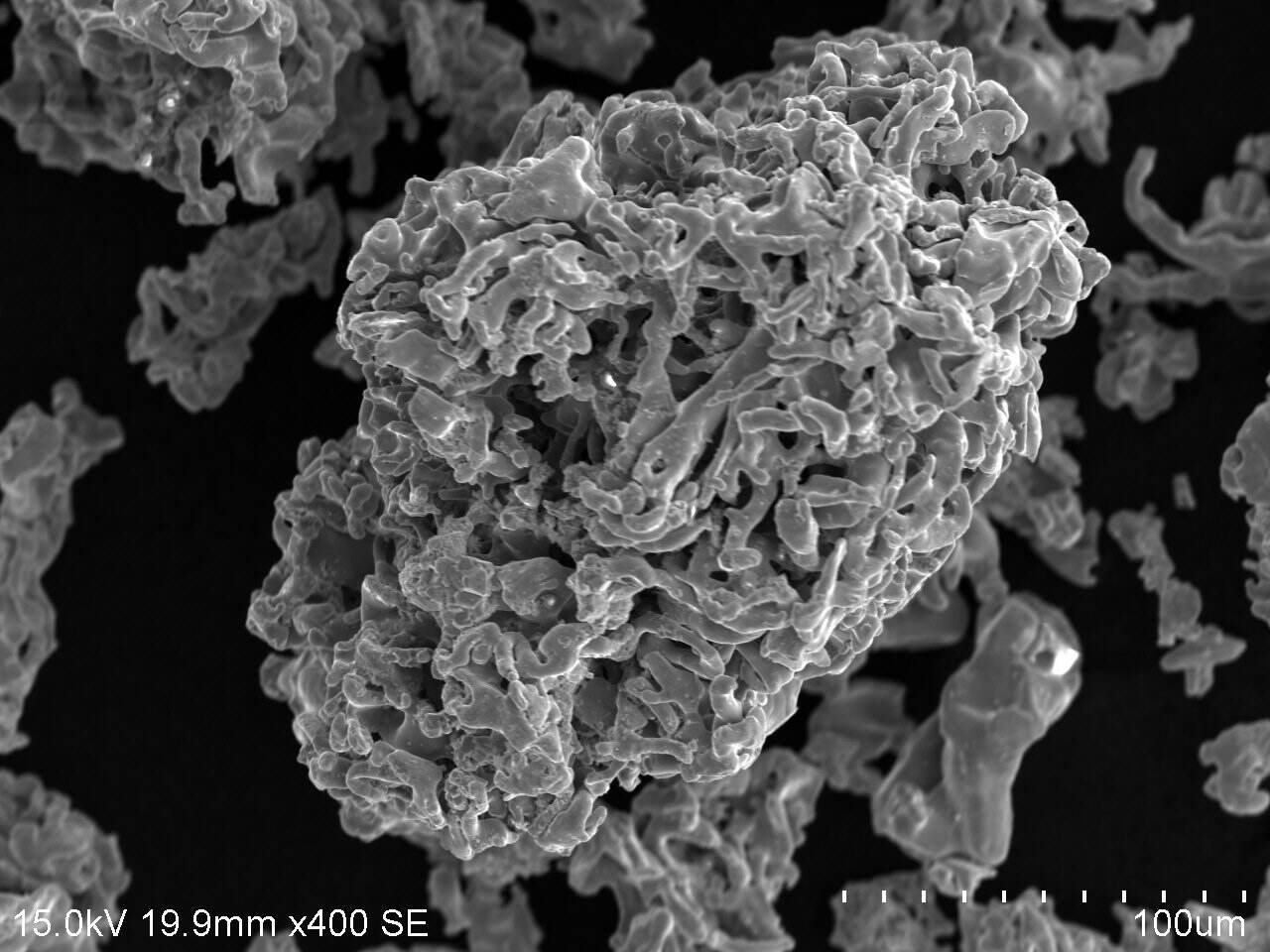

KPT is a very top-of-the-line brand that offers excellent Suppliers of Hydrogen Sponge Iron Powder Friction Material for Various Applications. This innovative product is the perfect solution for all your friction material needs.

The hydrogen sponge iron powder utilized in KPT's friction product is sourced from the quality materials which are greatest, ensuring long-lasting performance. This formula that is actually exclusive specifically made to present maximum durability and strength, even under extreme force and heats.

KPT's friction material is fantastic for an array of applications, which including automotive, aviation, marine, and also equipment that is commercial. It's perfect for use within brakes, clutches, and other systems being high-performance need very top-notch friction performances.

The product normally extremely versatile, and it will be tailor-made to satisfy the particular requirements of the application. KPT's expert team of specialists could work with one to supply a solution that is tailored perfectly meets your needs.

Among the key benefits of KPT's hydrogen sponge iron powders friction materials are its actually temperature that is excellent opposition. It can withstand temperatures that are extremely high compromising its performance, rendering it well suited for applications where heat is really a factor.

This product can be very resistant to put on and tear, supplying performance that is lasting under harsh conditions. It is built to deliver friction that is exceptional without causing extortionate wear on other elements, and also extending the life of the systems and reducing upkeep costs.

Get in touch with us today to learn more about Suppliers of Hydrogen Sponge Iron Powder Friction Material for Various Applications.

Chemical Properties | Unit | Specification | |||||||

ZTLD80 | ZTP100 | ||||||||

Min | Max | Min | Max | ||||||

H2-Loss | % | 0.4 | 1.4 | 0.5 | 1.3 | ||||

Acid insolubility | % | 0.6 | 0.5 | ||||||

Fe is Base | % | ||||||||

Physical Properties | |||||||||

Apparent density | g/cm3 | 1.6 | 2.2 | 2.3 | 2.5 | ||||

Particle size distribution | |||||||||

+80 mesh | % | 1 | 0.1 | ||||||

+100-80 mesh | % | 10 | 1 | ||||||

+140-100 mesh | % | 7 | 27 | 6.5 | 17.5 | ||||

+200-140 mesh | % | 18.5 | 30.5 | 17 | 31 | ||||

+325-200 mesh | % | 23.5 | 35.5 | 25.5 | 40.5 | ||||

-325 mesh | % | 11.5 | 35.5 | 19 | 41 | ||||

iron powder | Chemical Properties | Unit | Typical values(%) | Specification | ||||||

Min | Max | |||||||||

ZTR12 | C | % | 0.012 | 0.03 | ||||||

Mn | % | 0.35 | 0.65 | |||||||

P | % | 0.08 | 0.012 | |||||||

S | % | 0.009 | 0.05 | |||||||

HL | % | 0.5 | 2.5 | |||||||

Acid insolubility | % | 0.33 | 0.4 | |||||||

TFe | % | 98.1 | 97 | 98.5 | ||||||

ZTR80 | HL | % | 0.4 | 1.4 | ||||||

Acid insolubility | % | 0.4 | ||||||||

Fe is Base | % | |||||||||

Physical Properties | ||||||||||

ZTR12 | Apparent density | g/cm3 | 1.36 | 1 | 1.5 | |||||

Green density 212MPA | g/cm3 | 4.95 | 4.6 | 5 | ||||||

ZTR80 | Apparent density | g/cm3 | 1 | 1.5 | ||||||

Green density | g/cm3 | 5.8 | 6.1 | |||||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy