KPT

If you should be buying an alloy is top-quality is cobalt-based for laser cladding, you can't make a mistake with KPT's offering. Their cobalt-based alloy powder was created to provide performance is certainly exemplary a selection of applications, including aerospace, industrial manufacturing, and energy production.

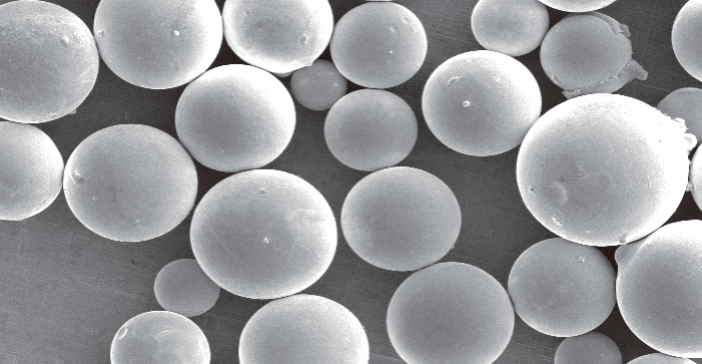

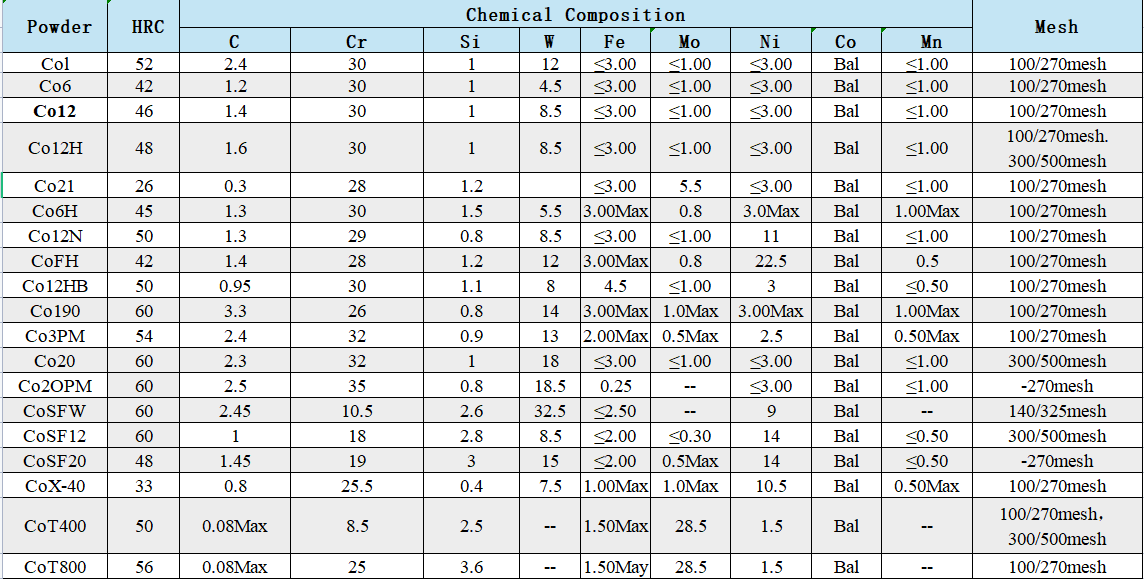

Precisely what sets KPT's cobalt-based alloy powder apart is its unique structure. The powder is established employing a mix of cobalt and other metals, including chromium, tungsten, and nickel. This blend provides the powder an amount is certainly a lot of and resistance to place on, corrosion, and environments are high-temperature.

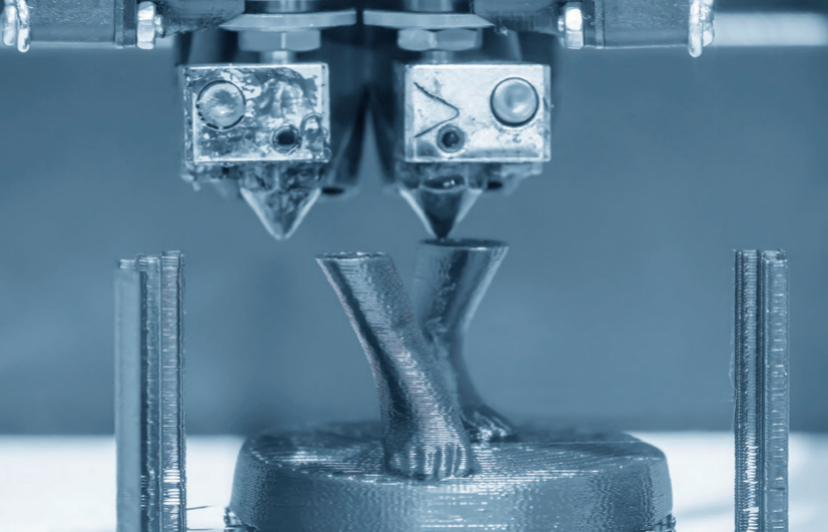

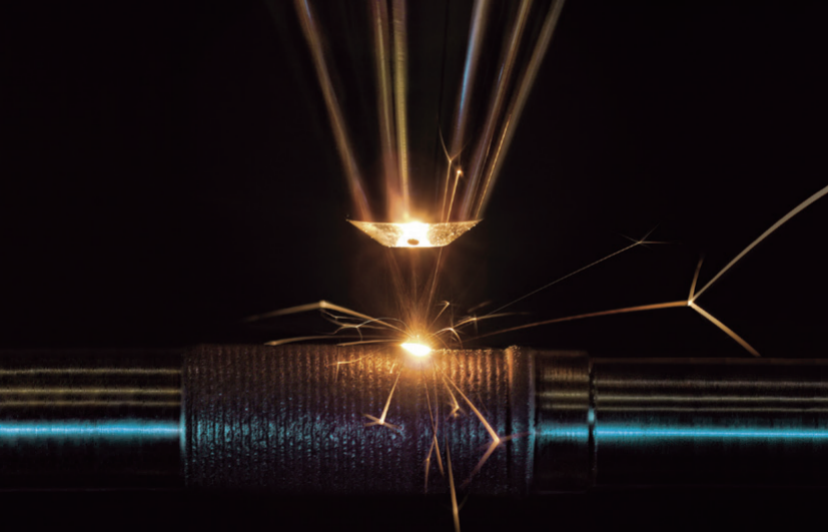

One of the most significant key features of KPT's cobalt-based alloy powder is its flexibility. The powder may be used in a variety of laser cladding applications, including layer and work is fix. Additionally it is appropriate used in a range of companies and may be employed to an array of areas, including metals, ceramics, and polymers.

Along with its versatility, KPT's cobalt-based alloy powder normally extremely efficient. The powder features a melting that is low, meaning it may be melted efficiently by means of a laser. This will make it and choice is ideal high-speed laser cladding applications, where rate and accuracy are essential.

Another asset that is advantageous cobalt-based alloy powder is its durability. The powder has been meant to offer protection this is certainly use is durable corrosion, even yet in the harshest of environments. This means you can rely on KPT's powder for high-stress applications where other coatings might fail.

Product name | Cobalt base alloy powder |

Color | grey |

Application | Surfacing and spray welding |

Certifications | REACH, ISO |

appearance | Visible Impurities |

ABOUT US:

The factory of KPT Co., Ltd. was founded in1987, after30 years of development, the company has become a modern large scale and promising powder manufacturer with advanced technology and sophisticated processing equipment. The company is the base of the national high-tech research and development program (863Program) industrialization achievement; the backbone enterprise for new material industrialization base;

The company’s annual production capacity has reached to 200,000 metric tons. The company has both sponge iron and atomized powder production line (water atomized, water & vapor combined atomized and inert gas atomized), is currently the largest and the most variety complete with fine quality powder production enterprise. The main kinds of products include sponge iron powder, atomized powder, stainless steel powder and iron soft magnetic powder. Products are rewarded as the "Shandong famous brand". All products are confirmed to IS09001 quality system. Products are widely used in automobile. Motorcycle, household applicants, welding, chemical industry, etc. Domestic market share has reached up to 25%. Products are sold well in 25 provinces and cities of China and exported to Japan, Korea, Vietnam, Thailand and other countries.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Laiwu district, Jinan city, Shandong Province, China. You can come to Shanghai first and transfer to our factory with us, or you can fly to Jinan city and we will pick you up at airport or high speed train station.

3. Q: How do I pay for my purchase order?

A: TT and LC

4. Q: How can I get some samples and how long will it take?

A: For small quantity sample, it is free, but the air freight is collect or pays us the cost in advance, we usually use International Express, and we will ship it to you after receipt of your charge.

5. Q: Do you have quality control system?

A: We do have quality control system for each step of process controlling, and we have the control system from raw material to finished products. We have many certificates of QA AND QC such as ISO certificate and IATF16949.

6. Q: What's the minimum order quantity?

A: 100grams.

7. Q: About Price:

A: The price is negotiable. It can be changed according to your quantity or package. When you are making an inquiry, please let us know the quantity you want. Some products we have in stock.

Remark your inquiries will be replied in 24 hours with our professional suggestions.

Welcome to contact us by Email, WeChat, Skype, WhatsApp, or Phone call.

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy