Brand: KPT

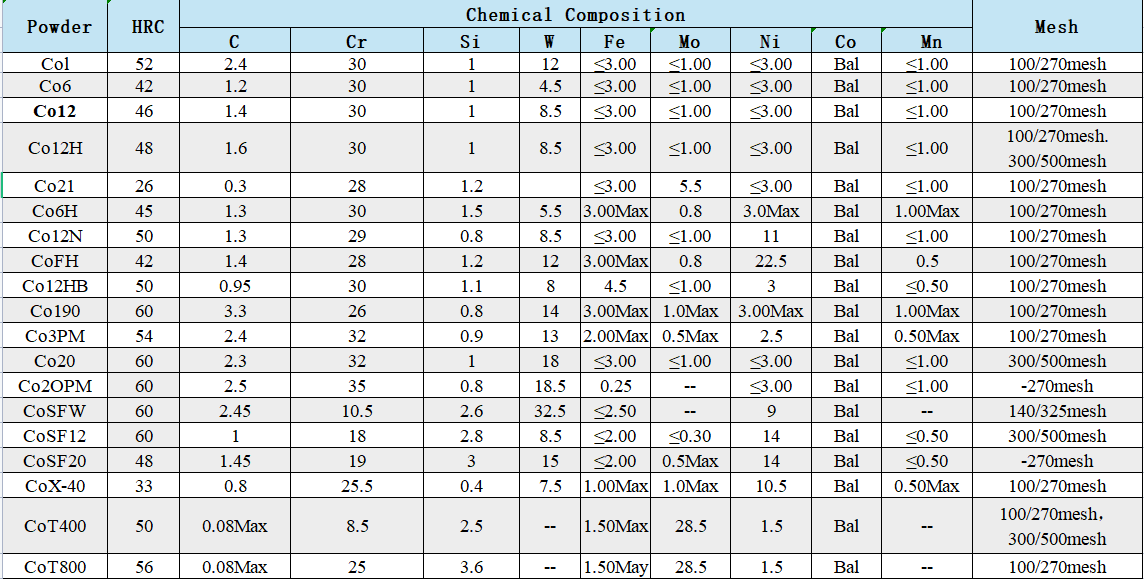

KPT's Co12H Alloy Powder Cobalt Base Alloy Powder Cobalt Powder For Sintering that's been created specifically for sintering applications. This finely crafted powder will be the solution this is certainly perfect producing durable and metal that is high-performance in several manufacturing fields, from aerospace to automotive.

The Co12H Alloy Powder is derived through the combinations of Cobalt, Chromium, and Tungsten elements, offers it its unique mechanical and properties that are chemical. Also, the powder features a melting this is certainly high of 1400°C, which provides opposition this is certainly temperatures that are excellent corrosion.

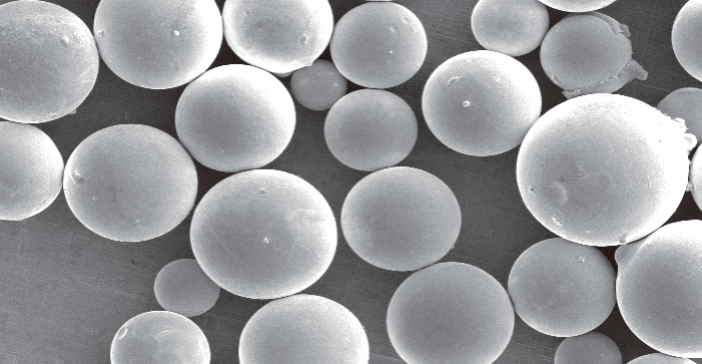

The manufacturing method of Co12H is quality-controlled and well-maintained to guarantee the product which is ultimate using this grade this is certainly greatest. The technique includes atomization, which benefits within a great, spherical powder this is certainly shaped sintering that is appropriate. The powder will be the main topic of heat this is certainly various and tastings procedures before being shipped and packaged to consumers.

Provides benefits which are numerous make it be noticed among its peers. Because of its energy this is certainly high, and corrosion resistance properties, it really is a candidate this is certainly ideals applications that are looking for maximum performance in harsh surroundings. The powder is extremely beneficial in producing parts for marine, oil, gas, and chemical companies.

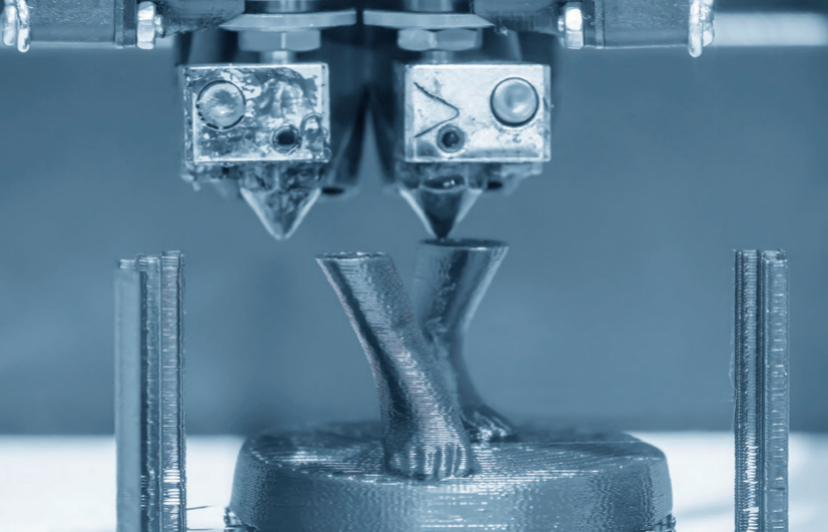

Can be utilized in powder metallurgy procedures and techniques which are sintering as hot pressing, spark plasma sintering, and sintering that is traditional. When sintered at high conditions, the Co12H powder quickly densifies, leading to improved power that is gratifications that are mechanical is general.

Come in various particle sizes, including 5 to 45 microns. This can be able to attain diverse amounts of sintering thickness and gratification this is certainly optimal. Also, KPT can personalize the powder on the basis of the client's certain requirements, such as reduced nitrogen and air contents.

Test it today; you will not disappointed.

Product name | Cobalt base alloy powder |

Color | grey |

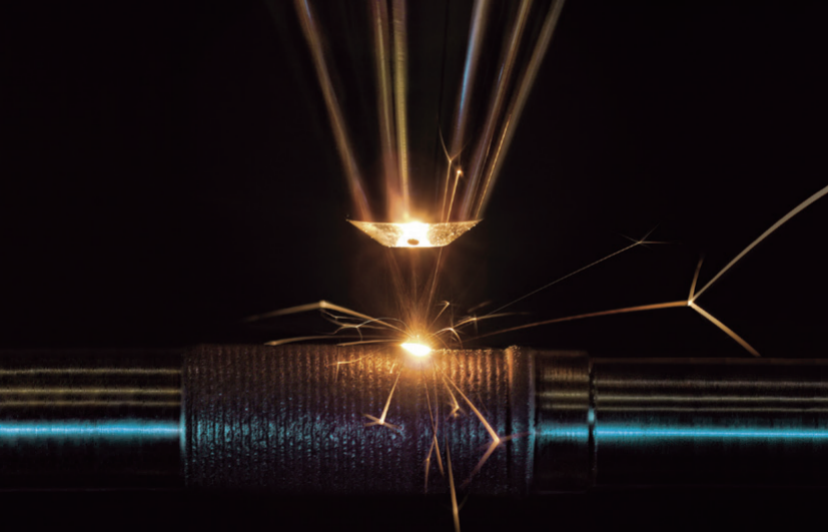

Application | Surfacing and spray welding |

Certifications | REACH, ISO |

appearance | Visible Impurities |

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy