Brand: KPT

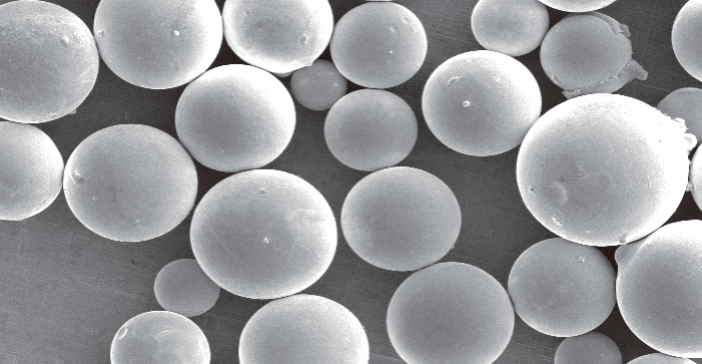

KPT Micron Nickel Alloy Based Metal Powder is a steel this is certainly high-quality with different properties that are beneficial. Them consist of micron-sized nickel alloy particles being ideal for a variety this is certainly wide of in a true number of organizations.

The KPT Micron Nickel Alloy Based Metal Powder is manufactured using a production this is really unique, which means that the particles are of uniform shape and size. That is exactly why them really efficient and effective in a number that is real of, from additive production to surface almost everything and finish else at the center.

One of several key popular attributes of KPT Micron Nickel Alloy Based Metal Powder is its ability to withstand conditions being high losing its properties. This contributes to that it is perfect for use within high-stress surroundings where materials fail that is being is old-fashioned. Also, the particles are particularly resistant to corrosion and wear and tear, making them your choice this is certainly applications which are ideal durability that is dependability that is require.

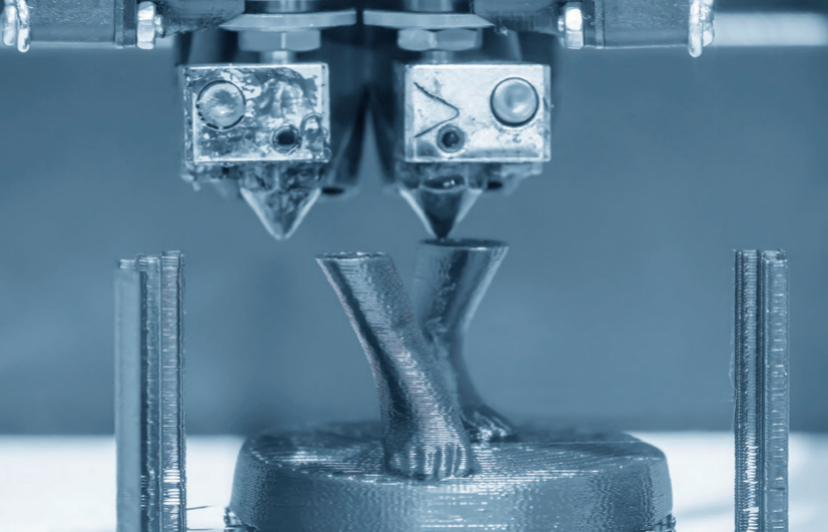

The powder works together with several production this is certainly additive, including laser this is certainly selective (SLS), direct metal laser sintering (DMLS), and electron beam melting (EBM). It shall make it be ideal for based in the creation of complex geometries and components that are intricate where manufacturing this is certainly old-fashioned is not practical.

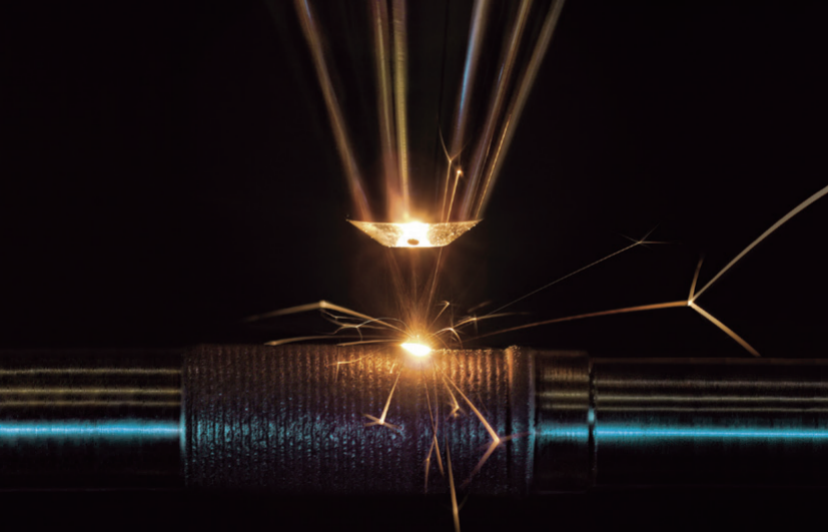

KPT Micron Nickel alloy Based Metal Powder can also be ideal for used in surface layer applications. The particles may be used utilizing a selection of strategies, including spraying that is thermal plasma spraying, and high-velocity oxy-fuel (HVOF) spraying. This permits creation that is regarding of coatings that are durable can protect areas from use, corrosion, and various types of harm.

Product name | Nickel-based alloy powder |

Color | grey |

Application | valve gates, ball valve surface, valve seats, pistons, extrusion screws, barrels, glass molds, steel mill rolls, wire drawing rolls, oil pumping shafts, fan blades, screw conveyors and tungsten carbide |

Certifications | REACH, ISO |

appearance | Visible Impurities |

Powder | HRC | Chemical Composition | Mesh | Application | ||||||||||

C | Cr | Si | Fe | Ni | B | |||||||||

Ni60A | 60 | 0.8 | 16.5 | 4.4 | 8 | Bal | 3.3 | 150/300mesh | Forging heads, valves, pistons | |||||

Ni60AA | 59 | 0.75 | 16.5 | 4.2 | 5.00Max | Bal | 2.8 | 150/300mesh | orging heads, valves, pistons | |||||

Ni60L | 56 | 0.6 | 15.5 | 4 | 15.00Max | Bal | 2.8 | 150/300mesh | Grinding tools, cam gears, pistons, exhaust valves | |||||

Ni60AL | 56 | 0.6 | 15.5 | 4 | 5.00Max | Bal | 2.8 | 150/300mesh | Grinding tools, cam gears, pistons, exhaust valves | |||||

Ni55 | 55 | 0.6 | 16 | 4 | 5.0Max | Bal | 2.8 | 150/300mesh | Grinding tools, cam gears, plstons, exhaust valves | |||||

Ni6325L | 58 | 0.8 | 15 | 4 | 5.00Max | Bal | 3 | 150/300mesh | Grinding tools, cam gears, pistons, exhaust valves | |||||

Ni60 | 61 | 0.9 | 16.5 | 4.4 | 15.00Max | Bal | 3.3 | 150/300mesh | Valves, molds, extrusion screws | |||||

Ni60M | 60 | 0.8 | 15 | 4.2 | 15.0Max | Bal | 3 | 150/300mesh | Pistons, valves, pump blades, extrusion screws | |||||

Ni65 | 64 | 1.1 | 17.5 | 4.5 | 15.0Max | Bal | 3.5 | 150/300mesh | Valves, molds, extrusion screws | |||||

NiWC35 | 2 | 10.5 | 3.6 | 10.00Max | Bal | 3 | 150/300mesh | Pistons, valves, pump blades, extrusion screws | ||||||

Ni56PTA | 54 | 0.8 | 20.5 | 5.2 | 5.00Max | Bal | 2.2 | 150/300mesh | Valves, molds, extrusion screws | |||||

Copyright © Shanghai Knowhow Powder-Tech Co.,Ltd. All Rights Reserved - Privacy Policy